❏

8. Slide the other wing panel onto the wing joiners and

press the two panels together. Clean up any epoxy that

squeezes out with a paper towel and alcohol.

❏

9. Press the wing panels together tightly to eliminate or

minimize any gap present and hold them together using

several pieces of masking tape. Set the bottom wing aside

and allow the epoxy to fully cure before proceeding.

❏

10. Position the wing bolt plate over the wing bolt holes

in the wing. Trace the outline of the plate on the wing. Trim

away the covering on the plate, about 3/32" [2.4mm] inside

of the outline and glue the wing bolt plate in place as shown

using medium CA.

❏

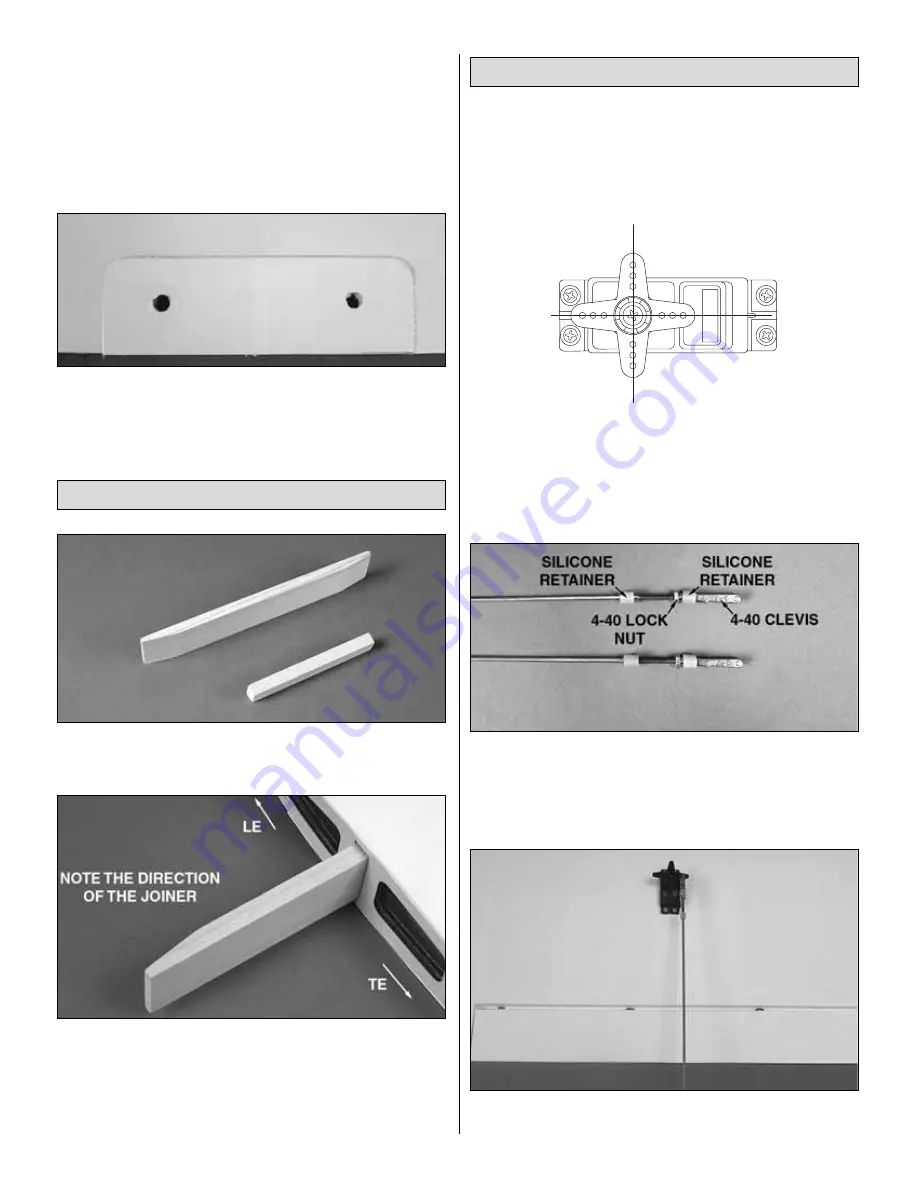

1. Locate the two hardwood wing joiners for the top wing.

The larger wing joiner should have angled ends as shown in

the photo. Measure and mark the centerlines on the joiners.

❏

2. Test fit the wing joiners in the wing joiner pockets. Note

the direction of the main wing joiner. Sand the wing joiners

as needed for a good fit.

❏

3. Join the wing following the same technique as done

with the bottom wing.

❏ ❏

1. The following photos and procedures will show the

connection of a bottom wing servo pushrod. The

procedure will be the same for all aileron servos.

❏ ❏

2. Make sure all trims and sticks are centered on your

radio system. Temporarily connect the aileron servo to the

radio system and center it. Attach a servo horn to the servo

so that the arms are aligned as shown.

❏ ❏

3. Locate one 4-40 x 12" [305mm] pushrod. Assemble

the pushrod end as shown. The clevis should be threaded 14

turns onto the threaded end of the pushrod.

❏ ❏

4. Attach the clevis to the 3rd hole out on the servo arm.

Align the pushrod at a 90° to the arm and aileron as shown.

Connect the Ailerons Pushrods

Join the Top Wing

11