❏

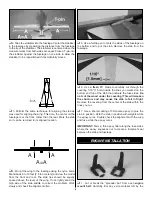

1. Use thin cardboard or plastic to make templates

locating the firewall and forward fuselage.

❏

2. Slide the

cowl

over the engine and fuselage. Install the

spinner backplate and center the cowl 3/32" to 1/8" [2.5mm

to 3mm] behind the spinner backplate. Tape the cowl in

position and place four marks (two on each side of the cowl)

for the cowl mounting screws using the templates.

❏

3. Drill a 3/32" [2.5mm] hole through the cowl and fuse at

each mark. Remove the cowl and enlarge the holes in the

cowl only

to 1/8" [3mm]. With the cowl removed, apply a

couple of drops of thin CA to the cowl mounting holes in the

fuse to harden the wood. This will prevent the holes from

stripping out during flight. After the CA has cured, attach the

cowl to the fuse with four

#4 washers

and four

#4 x 5/8"

sheet metal screws.

❏

4. Remove the cowl and use a piece of thin cardboard or

plastic to make templates for the cutout in the cowl for the

glow plug, needle valve and exhaust. Tape the templates to

the fuselage side, accurately indicating the position of the

cylinder head.

❏

5. Remove the engine and install the cowl. Transfer the

glow plug, needle valve and exhaust holes from the

templates onto the cowl.

❏

6. Remove the cowl and templates, then remount the

engine. Cut out the holes in the cowl, then test fit it to the

fuselage. You may want to make the cuts slightly smaller

than the template outline to allow for adjustment. Adjust the

position and size of the holes as needed.

Note:

There are three holes in the fuel tank stopper but only

two are used for this model. Do not puncture the third hole

in the stopper.

❏

1. Push one

short aluminum tube

and one

long

aluminum tube

through the

rubber stopper

until 1/2"

[13mm] of the tubes protrudes from the front of the stopper.

Slide the

large

cap onto the front of the stopper, and the

small cap

onto the back. Insert the

stopper screw

into the

center hole in the front cap, then screw it through the stopper

into the aft stopper cap. Just start the threads in the aft cap

or you won’t be able to insert the stopper into the tank.

❏

2. Push one end of the

silicone pickup tube

all the way

onto the

clunk,

and the other end all the way onto the short

aluminum tube. Bend the long aluminum (vent) tube upward

at about a 45º angle, being careful not to kink the tube.

FUEL TANK INSTALLATION

COWLING INSTALLATION

10