❏ ❏

7. Thread a 4-40 hex nut and a 4-40 clevis onto the

threaded end of the pushrod wire. Attach the clevis to the

control horn.

❏ ❏

8. Use a felt-tip pen to mark the pushrod wire where it

crosses the holes in the aileron servo arm. Cut the pushrod

wire 3/4" [19mm] behind the mark.

❏ ❏

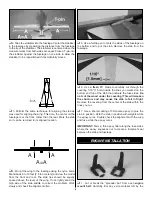

9. Locate a solder clevis. Use the following sequence

to solder the clevis to the pushrod:

❏ ❏

A. Lightly sand the pushrod and clean it with alcohol.

❏ ❏

B. Insert the pushrod into the non-threaded clevis. The

wire should protrude 1/16" [1.5mm] inside the forks of the

clevis.

❏ ❏

C. Apply a small amount of soldering flux to the joint.

❏ ❏

D. Apply heat evenly to the pushrod and the clevis and

then touch the solder to the joint and allow it to flow.

❏ ❏

E. Allow the pushrod and clevis to cool slowly before

continuing.

❏ ❏

10. Place a clevis retainer onto both of the clevises.

Attach the pushrod to the servo and control horn.

❏

11. Return to step 3 and connect the other elevator servo

to the other elevator the same way.

Note:

The procedure for installing the rudder to the fin is

similar to the installation of the elevators.

❏

1. Cut two 3/4" x 1" [ 19mm x 25mm] hinges from the CA

hinge strip supplied with this kit. Cut one 1-1/2" x 1" [38mm

x 25mm] hinges from the CA hinge strip supplied with this

kit. This larger hinge is used as the bottom hinge on the

rudder. The hinge is positioned vertically in the slot. Snip the

corners off so they go into the slots easier.

❏

2. Test fit the rudder to the fin. If the hinges are difficult to

install or don’t go in far enough, carefully enlarge the hinge

slots with a hobby knife and a #11 blade.

❏

3. Drill a 3/32" [2.5mm] hole, 1/2" [13mm] deep, in the

center of the hinge slot. Drill two evenly spaced holes for the

bottom hinge. If you use a Dremel MultiPro for this task, it

will result in a cleaner hole than if you use a slower speed

drill. Drilling the hole will twist some of the wood fibers into

the slot, making it difficult to insert the hinge, so you should

reinsert the knife blade, working it back and forth a few times

to clean out the slot.

❏

4. If the hinges don’t remain centered, remove the rudder

and insert a pin in the center of the hinges.

❏

5. Cut a paper towel into approximately 2" [50mm]

squares. Add six drops of thin CA to the center of the hinges

on both sides. Use the paper towel squares to absorb

excess CA from the hinge gap before it cures. Do not use

CA accelerator; allow the CA to cure slowly.

❏

1. Locate the hole for the Rudder Servo and remove the

covering from the side of the fuselage using a sharp hobby

knife. Do not cut into the underlying wood, as this will

weaken the structure and could cause a failure in flight. Seal

down the edges with the Trim Seal Tool. Use 6-minute

epoxy to fuelproof any exposed wood.

❏

2. Install the rubber grommets and eyelets on your rudder

servo. Attach a servo extension to the rudder servo. Use

heat shrink tubing or electrical tape to secure the servo lead

to the extension so it doesn’t unplug in flight. Drop the

extension into the fuselage.

❏

3. Fit the rudder servo in the fuselage. Hold the servo to

the fuselage so the sides don’t contact the fuselage and drill

1/16" [1.5mm] holes for the servo mounting screws.

Remove the servo and wick a few drops of thin CA into each

of the four holes. Mount the servo to the fuselage with the

screws included with your servos.

❏

4. Cut the unused arms from one of your servo horns and

mount it to your rudder servo. The remaining arm faces the

bottom of the fuselage.

Install the Rudder Servo

Attach the Rudder

16