(or downward) all the way. Manually close the throttle on the

carburetor completely. Tighten the cap screw on the screw-

lock pushrod connector. Check throttle operation with the

radio and make adjustments to the linkages as necessary

for smooth operation. Use the appropriate holes in the servo

and throttle arms to provide the correct amount of throttle

movement and to prevent the servo from binding at its end

points. Once everything is adjusted, install a spare piece of

balsa as a brace near the servo for the outer pushrod

housing.

❏

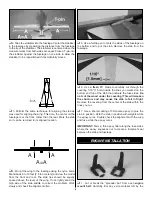

1. Hook up - following the manufacturer’s recommendations

- the receiver, switch and battery as shown in the photo. We

added a Great Planes Switch Mount & Charge Jack

™

(GPMM1000, not included) for convenience and ease of use

at the field, installed on the side of the fuselage. At this time,

it is suggested to allow the receiver and battery the option of

being moved until after the aircraft has been balanced. Once

balanced, the receiver and battery should be secured into

the aircraft to prevent them from moving during flight. Plug

the servo extensions for the elevator and rudder servos, as

well as the extensions for the aileron servos, into the

receiver at this time.

❏

2. Route the antenna to the tail of the model. You may

use your preferred method or the method we use in the

Great Planes model shop. Drill a 15/64" [6mm] hole through

the fuse side in the proximity of the receiver. Cut a 1/2"

[13mm] long piece of fuel tubing and install it in the hole.

Install a strain relief (as shown in the sketch), then route the

antenna through the fuel tubing to the bottom of the fuse at

the tail. Use a rubber band to attach the antenna to a T-pin

at the aft end of the fuselage. Do not cut or shorten the

antenna wire. Leave any excess to hang free.

❏

1. Fit approximately 12" to 14" [300mm to 360mm] of fuel

line on the pick-up and vent nipples of your fuel tank. Attach

the fuel lines from the fuel tank to the engine, making sure

the fuel and pressure lines are correctly attached. Be certain

you do not kink the fuel lines.

Note:

If your engine’s carburetor is inaccessible with the

cowl in position, now would be a good time to add a Great

Planes Fuel Filler Valve

™

(not included, GPMQ4160) to the

side of your aircraft. Instructions for installation are included

with the valve.

❏

2. Locate the clear

canopy

and carefully trim along the

cut lines with scissors or Lexan

®

shears. Test fit the canopy

on the fuse as you proceed, making small adjustments as

required for a good fit.

❏

3. Paint the exposed wood behind the canopy with black

paint. Install a pilot if so desired. You can use Top Flite

LustreKote

®

without any special preparations to the paint or

the model. Just make sure to mask off any areas you do not

want painted.

❏

4. Roughen the bottom 1/8" [3mm] of the inside canopy

edge, being careful not to scratch any exposed areas. Glue

the canopy into position with 6-minute epoxy or R/C-56 glue.

❏

5. Attach the wing to the fuselage using the 1/4-20 x 2"

nylon bolts. Test fit the

belly pan

onto the wing. Trim the

belly pan as necessary to provide a tight fit against the wing.

Trace around the outside of the belly pan using a felt-tip marker.

❏

6. Remove the belly pan and remove a 1/2" [13mm] wide

strip of covering 1/16" [1.5mm] inside the line drawn. Using

30-minute epoxy, glue the belly pan to the wing.

FINAL ASSEMBLY

Receiver & Battery Installation

19