34

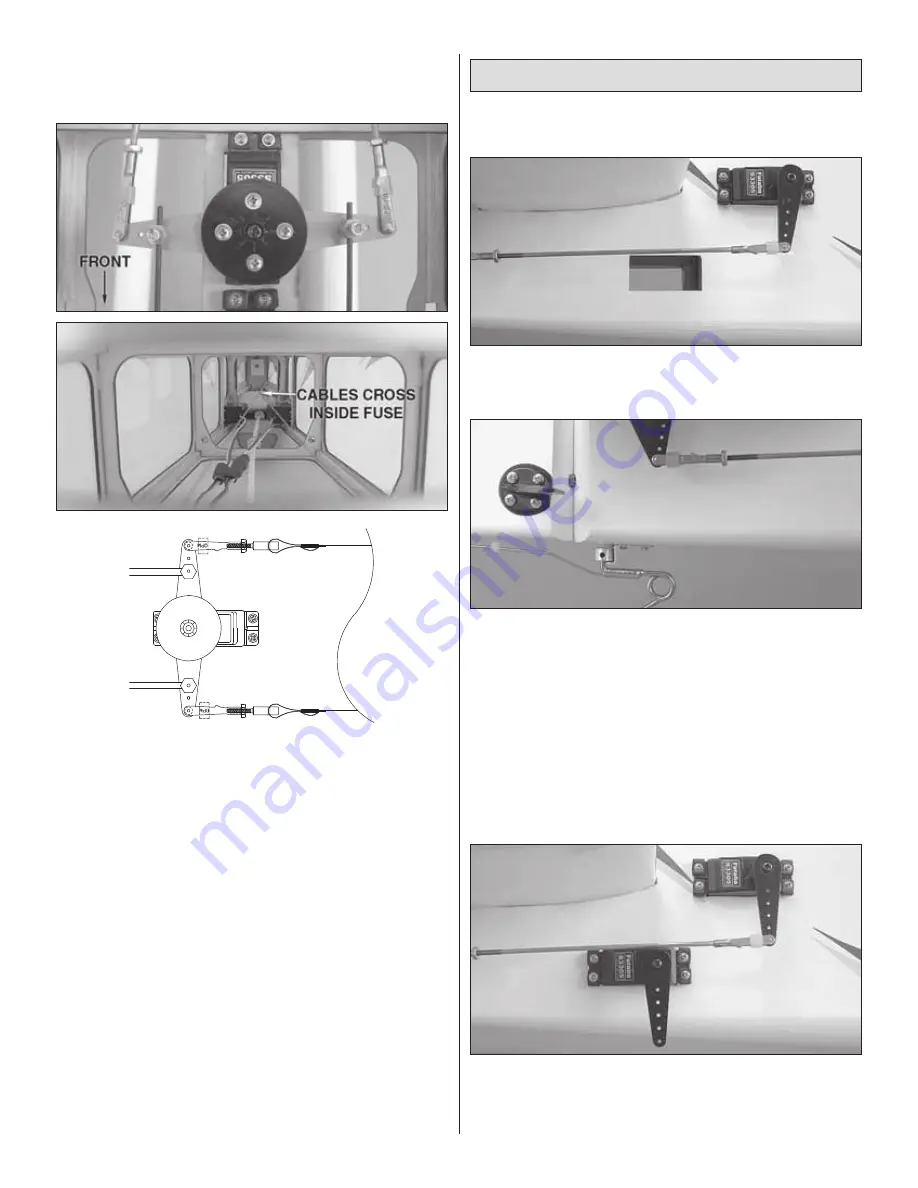

the forward rudder servo. Insert the two rudder servo joiner

rods (included with the kit) through the screw-lock pushrod

connectors as shown and tighten all the 4-40 SHCS.

❏

11. Connect the other two clevis ends with the brass

couplers installed onto the outer holes of the aft rudder servo

extension. Check to be sure that the elevator servo wires are

not entangled in the rudder pull-pull cables. Slide a swage

onto the ends of the pull-pull cables inside the fuse. Move the

rudder to the neutral position and feed the ends of the cables

through the holes in the brass couplers. The pull-pull cables

will cross each other inside the fuse. With both pull-pull

cables having tension and the rudder in the neutral position,

crimp the swages onto the cable ends to secure them as

you did in step 4. You can fi ne-tune the tension on the lines

by threading the clevises up or down on the couplers until

satisfi ed. Then, tighten the 4-40 nuts against the clevises

and slide the silicone clevis retainers over the clevises. Be

sure that the rudder is in the neutral position when the cables

are both tight and the rudder servos are perpendicular to the

fuse. Note: If the rudder servo extensions contact the throttle

servo when using the forward radio tray, move the throttle

servo all the way to the side of the tray and fl ip the position

of the throttle servo arm.

Install the Rudder Servos in the Aft Position

This is the recommended installation for gas engines.

❏

1. Trim the covering from the aft rudder servo bays leaving

1/8" [3mm] around the opening. Use a trim iron to seal down

the covering around the edges of the servo bays.

❏

2. Locate the plywood mounting plates beneath the

covering on both sides of the rudder. Place a heavy duty

nylon control horn on each side of the rudder, positioning

them as shown. To avoid putting stress on the clevis pins, tilt

the control horns at a slight downward angle (approximately

2 to 3 degrees). Mark the location for the screw holes. Drill

through the marks you made with a 3/32" [2.4mm] drill bit.

Be sure you are drilling through the plate only! Do not

drill all the way through the rudder. Using a #4 x 5/8" [16mm]

self-tapping screw, install and then remove a screw into each

of the holes. Harden the holes with thin CA. Install the control

horns with eight #4 x 5/8" [16mm] self-tapping screws.

❏

3. Attach a 36" [914mm] servo extension to each rudder

servo. Secure the servo extensions with the included heat-

shrink tubing. Feed the servo extensions through the fuse

and install the servos into the servo bays with the splines

Summary of Contents for GPMA1412

Page 52: ......