35

facing forward using the mounting hardware included with the

servos. Be sure to harden the servo mounting screws with

thin CA. Attach the servo arms pointing down as shown.

❏

4. Assemble the rudder pushrods using two .095" x 12"

[2.4mm x 305mm] pushrod wires threaded on one end, two

4-40 clevises, two 4-40 nuts, two solder clevises, and four

silicone clevis retainers. Just as you did with the aileron and

elevator pushrods, mark and cut the pushrods to length,

solder the clevises to the pushrods, and attach the pushrods

to the elevators. Secure the clevises with silicone clevis

retainers. Be sure to use threadlocking compound on the

pushrod threads.

FINISH THE MODEL

Install the Radio System

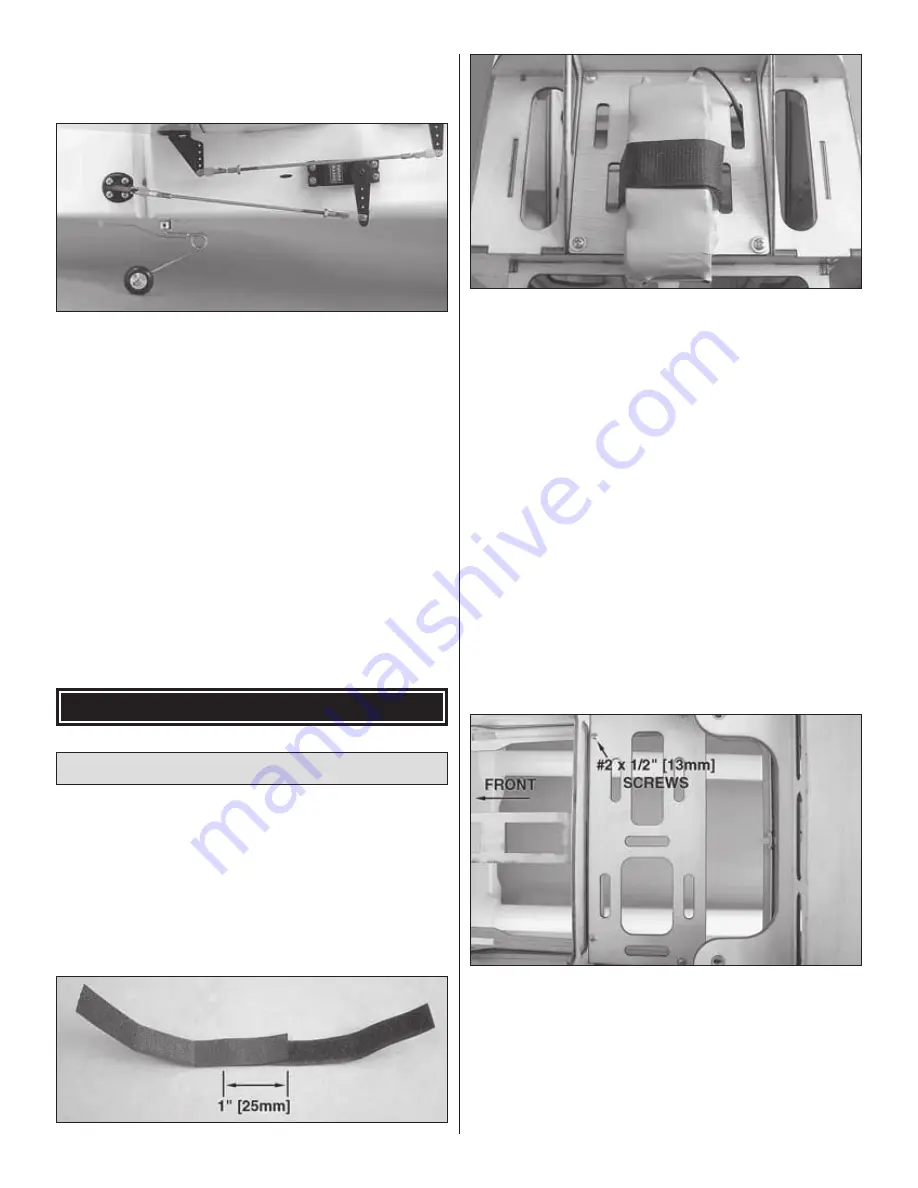

Note: There are multiple locations to install the receiver and

receiver battery pack depending on the power system being

used and the ballast needed to balance the airplane at the

recommended point. A plywood auxiliary battery tray is included

and can be secured to the top of the motor mounting box. A

forward and aft radio tray are also provided that will accommodate

both components. Read through the radio installation steps and

choose the location that best suits your setup.

❏

1. If weight is needed at the nose of the model for balancing

purposes, install the auxiliary battery tray. Make a strap by

overlapping the mating ends of the included non-adhesive

hook and loop material by approximately 1" [25mm]. The

total length of the strap you make will be determined by the

size of the receiver battery pack you will be using. Loop the

strap through the slots in the tray that best match the width

of the battery pack. Place the auxiliary battery tray over the

opening on the fuse behind the motor mounting box. Mark

the position of the four mounting holes in the tray onto the

fuse and use a 3/32" [2.4mm] bit to drill pilot holes at your

marks. Thread a #4 x 3/8" [9.5mm] self-tapping screw into

each hole and remove it. Apply a couple drops of thin CA

to each hole to harden the wood. Attach the tray to the fuse

using four #4 x 3/8" [9.5mm] self-tapping screws and four

#4 fl at washers. Cut a piece of 1/4" [6mm] foam rubber (not

included) to match the shape of the battery pack and use

the hook and loop strap to secure the battery pack in place

on the tray.

❏

2. If you have installed a brushless motor or gas engine,

you will need to install the aft radio tray. Position the tray

in place as shown and use a 1/16" [1.6mm] drill bit to drill

four holes through the two aft radio tray mounting blocks

and the balsa rail along the fuse former. Thread a #2 x 1/2"

[13mm] self-tapping screw into each hole and remove it.

Apply a couple drops of thin CA to each hole to harden the

wood. Secure the tray with four #2 x 1/2" [13mm] self-tapping

screws and four #2 fl at washers.

Summary of Contents for GPMA1412

Page 52: ......