❏ ❏

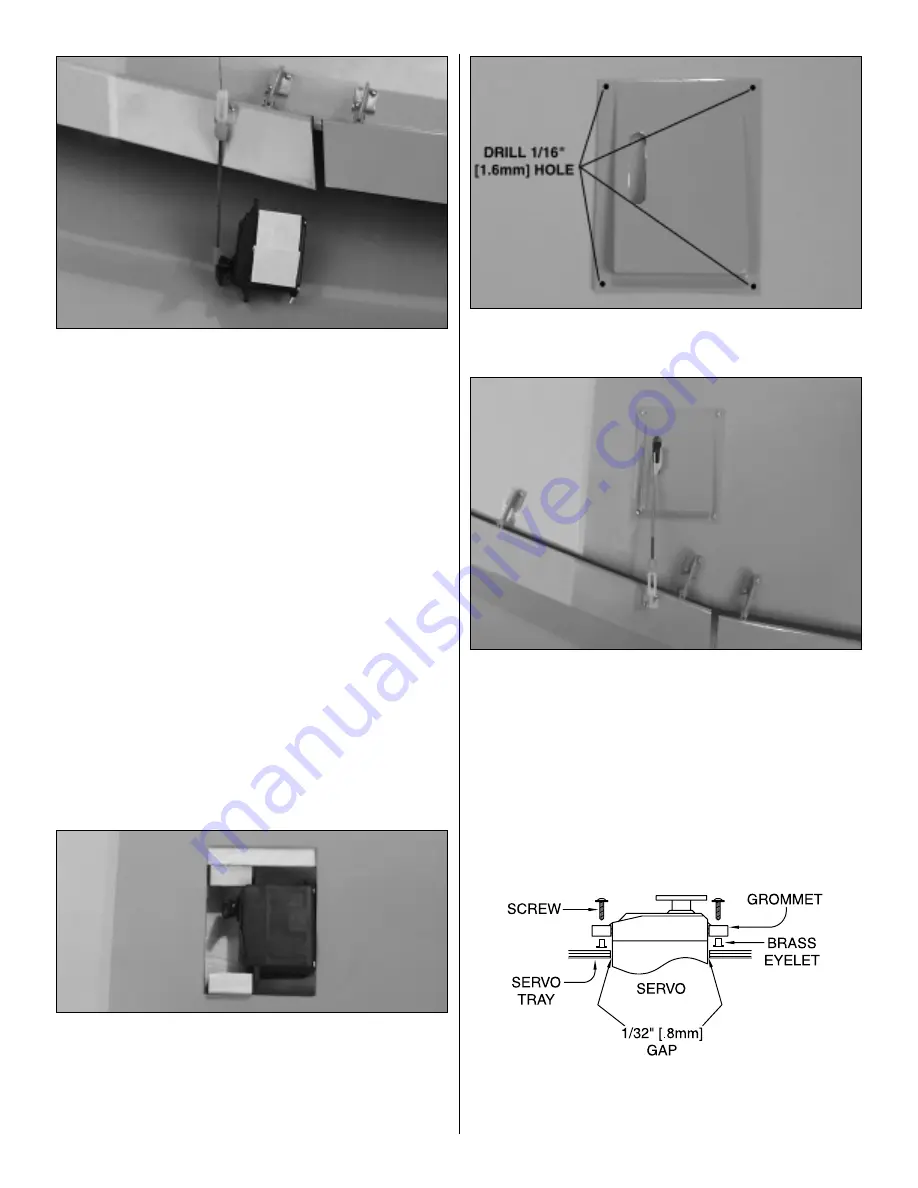

11. (Important: Before starting step 11, be sure the

servo is properly centered. If you have any doubt,

re-center the Servo.) Leave the pushrod wire attached to

the servo horn and the control horn. Remove the servo from

the servo bay. Apply two 1" [25mm] squares of double faced

servo tape (included in kit) to the servo. Then place the

servo back into the servo bay, making sure the bottom of the

servo is resting against the side of the servo bay as shown

in step 12. (Be sure to pull the string that is attached to the

servo lead, pulling the lead through the wing as you mount

the servo.) Apply pressure to the servo so that the servo

tape gets good adhesion to the servo bay.

❏ ❏

12. Remove the nylon FasLink and the pushrod wire

from the servo horn. Locate two 3/8" x 3/4" x 3/4" [9.5 x 19

x 19mm] hardwood blocks. Place them against the servo

mounting tabs so that they act as a wedge forcing the servo

against the side of the servo bay. Using 6-minute epoxy, glue

them in the servo bay but do not glue them to the servo.

❏ ❏

13. Cut out the ABS servo cover as shown. Drill a 1/16"

[1.5mm] hole in each corner of the cover.

❏ ❏

14. Place the cover in position over the servo bay. Drill

a 1/16" [1.5mm] hole into the wing through each of the holes

in the corner of the servo cover. Put a drop of thin CA into

the holes in the wing. This will strengthen the holes. Allow

the glue to cure and then screw the cover to the wing with

four #2 x 3/8" [9.5mm] machine screws. After the cover is

installed, re-attach the pushrod clevis retainer and nylon

FasLink.

❏

15. Repeat steps 2 to 14 for installing the servo in the

left wing.

❏ ❏

16. Following the manufacturer’s instructions for your

radio system, install the rubber grommets and eyelets onto

a flap servo.

23