To order replacement parts for the Great Planes Stuka ARF, use the order numbers in the Replacement Parts List that

follows. Replacement parts are available only as listed. Not all parts are available separately (an aileron cannot be

purchased separately, but is only available with the wing kit). Replacement parts are not available from Product Support,

but can be purchased from hobby shops or mail order/Internet order firms. Hardware items (screws, nuts, bolts) are also

available from these outlets. If you need assistance locating a dealer to purchase parts, visit www.greatplanes.com and

click on “Where to Buy.” If this kit is missing parts, contact Great Planes Product Support.

Replacement Parts List

Order Number

Description

How to Purchase

Missing pieces ......................Contact Product Support

Instruction manual.................Contact Product Support

Full-size plans .......................Not available

GPMA2220......................................Wing Kit

GPMA2221......................................Fuse Kit

GPMA2222......................................Tail Set

Contact Your Hobby

GPMA2223......................................Cowl

Supplier to Purchase

GPMA2224......................................Canopy

These Items

GPMA2225......................................Landing Gear

GPMA2226......................................Wheel Pants

• There are two types of screws used in this kit:

Sheet metal screws are designated by a number and a

length. For example #6 x 3/4".

This is a number six screw that is 3/4" long.

Machine screws are designated by a number, threads per

inch, and a length. For example 4-40 x 3/4".

This is a number four screw that is 3/4" long with forty

threads per inch.

• When you see the term

test fit in the instructions, it means

that you should first position the part on the assembly

without using any glue, then slightly modify or custom fit the

part as necessary for the best fit.

• Whenever the term

glue is written you should rely upon

your experience to decide what type of glue to use. When a

specific type of adhesive works best for that step, the

instructions will make a recommendation.

• Whenever just

epoxy is specified you may use either

30-minute (

or 45-minute) epoxy or 6-minute epoxy. When

30-minute epoxy is specified it is highly recommended that

you use only 30-minute (or 45-minute) epoxy, because you

will need the working time and/or the additional strength.

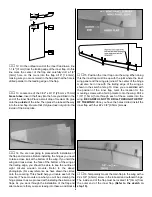

• Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

Fuse = Fuselage

Stab = Stabilizer

Fin = Vertical Fin

LE = Leading Edge

TE = Trailing Edge

LG = Landing Gear

Ply = Plywood

" = Inches

COMMON ABBREVIATIONS

IMPORTANT BUILDING NOTES

4

ORDERING REPLACEMENT PARTS

................