7

❏ ❏

5. Tie the guide string to the end of the servo lead and

carefully route the servo lead through the wing and out of the

hole in the sheeting near the root rib of the wing.

❏ ❏

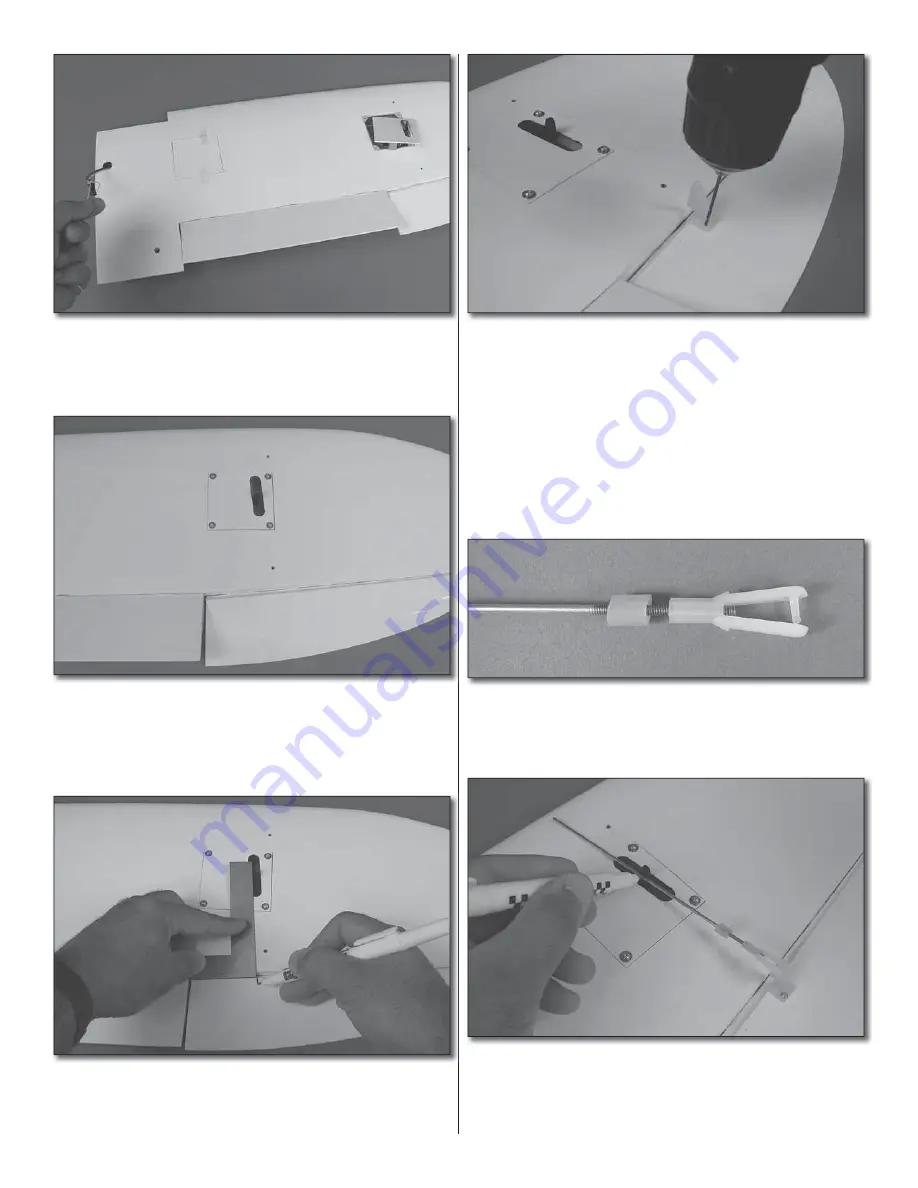

6. Orient the servo bay cover as shown and install it

using four #2 x 3/8" [9.5mm] sheetmetal screws with four

#2 flat washers. Remove the screws, washers and the cover

and harden the screw holes in the wing with thin CA. Then,

re-install the cover and screws.

❏ ❏

7. Using a 90° builder’s square or a builder’s triangle,

make a mark on the aileron directly behind the aileron servo

arm. Align the flat base of the square with the aileron hinge

line. Then slide the square into position and make your mark.

❏ ❏

8. Clip off and discard the backing plate from a small

control horn. Align the horn over the mark you made and

slide it forward until the pushrod holes in the horn are directly

over the hinge line. Drill two 3/8" [9.5mm] deep holes using a

1/16" [1.6mm] drill. Be careful not to drill completely through

the aileron.

❏ ❏

9. Install the control horn using two #2 x 3/8" [9.5mm]

sheetmetal screws. Remove the screws and the horn and

wick about 4-5 drops of thin CA into the screw holes you

tapped. Allow the CA to dry and reinstall the control horn.

❏ ❏

10. Screw a clevis onto a 6" [152mm] threaded pushrod

so that at least 1/8" [3.2mm] of thread protrudes past the

barrel of the clevis. Loosely fit a silicone clevis retainer to the

pushrod.

❏ ❏

11. Fit the clevis to the outermost hole in the aileron

control horn. Extend the pushrod forward and align it with

the hole you drilled in the servo arm. With the servo arm

centered and the aileron at neutral, make a mark at the hole

in the servo arm.