Note: Throughout the rest of the assembly process you

will be installing different types of metal brackets. These

are diagrammed below. Pay close attention to each metal

bracket to make sure you are using the correct one for

each particular application and that they are oriented as

shown in the photographs. Also note that the holes in

each bracket are of a different size. The larger hole allows

the mounting screw to pass through and the smaller hole

is for attachment of the metal clevis.

❏

1. Locate the four predrilled holes in the bottom of the top

wing center section.

IMPORTANT NOTE: IN THE FOLLOWING STEP IT IS VERY

IMPORTANT TO INSTALL THE TWO 90-DEGREE

BRACKETS PROPERLY. THESE BRACKETS HAVE ONE

SIDE THAT IS LONGER THAN THE OTHER. WHEN

INSTALLED CORRECTLY THERE SHOULD BE NO GAP

BETWEEN THESE BRACKETS. IF THERE IS A GAP THEY

ARE INSTALLED WRONG. CHECK THE PHOTOGRAPH

ON PAGE 15, STEP 8 FOR THE PROPER POSITION OF

THESE BRACKETS.

❏

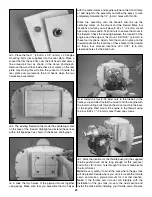

2. Using the technique described on Page 8, install two

90-degree metal brackets (Bracket D, as shown above) into

the pre-drilled holes in the front of the bottom of the top wing

center section with two #4 x 1/2" (13mm) wood screws.

Mount two 90-degree compound bend metal brackets

(Bracket C, as shown above) using two #4 x 1/2" (13mm)

wood screws. The cabane struts and flying wires will attach

to these "C" brackets in a later step.

❏

3. Next locate the four predrilled holes in the two outer

panels of the bottom of the top wing just outboard of the

aileron servos.

❏

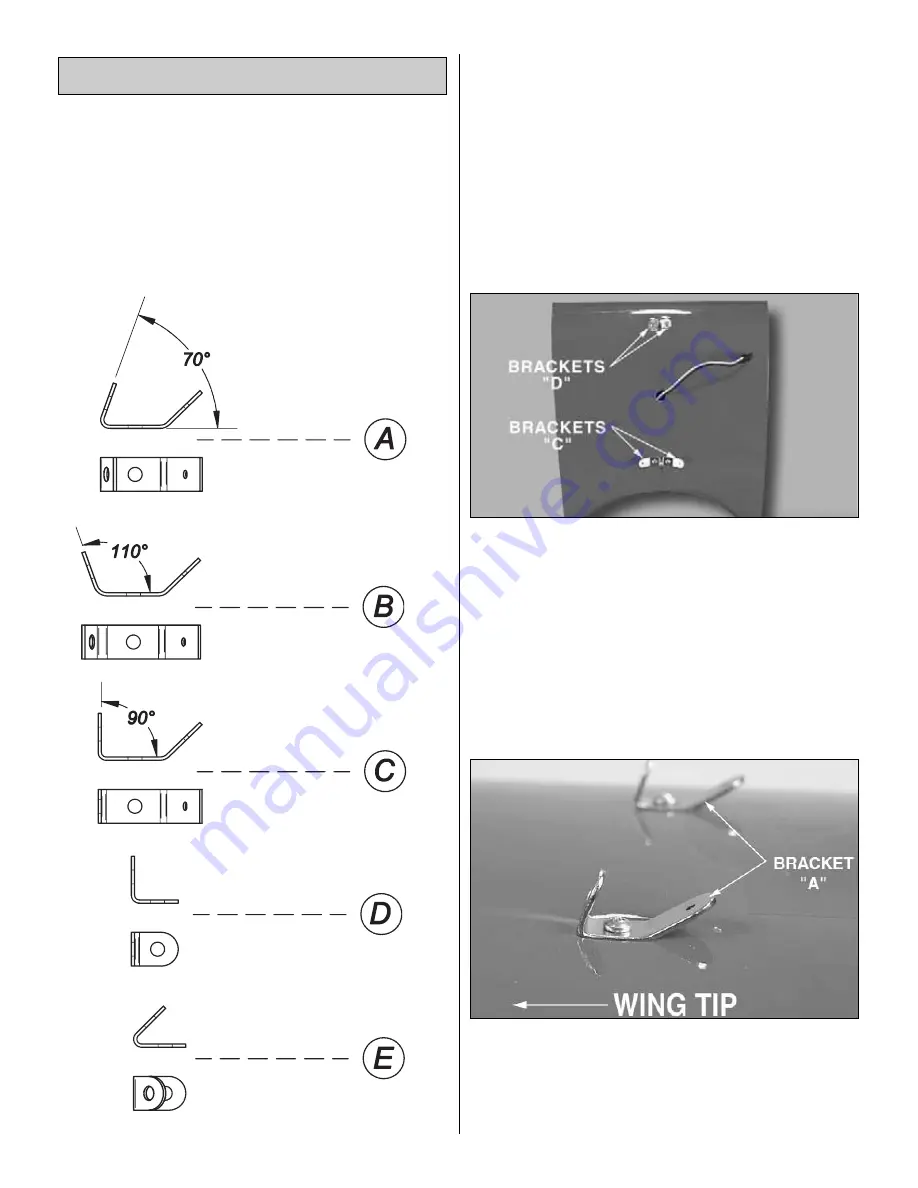

4. Again, using the technique described on Page 8, install

the four 70-degree compound bend metal brackets (Bracket

A, as shown in the diagram) in place (two on each wing

panel) with four #4 x 1/2" (13mm) wood screws as shown in

the photo above. The orientations of these brackets are

shown in the photograph.

70˚ Bracket

90˚ Bracket

90˚

Compound

Bend Bracket

110˚

Compound

Bend Bracket

70˚

Compound

Bend Bracket

Mount the Top Wing

14