technique that was used while adding the belly pan onto the

bottom wing. Again, be careful not to cut into the wood while

removing the MonoKote.

❏

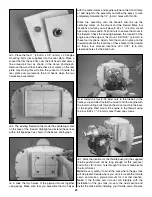

6. Slide the stab back into the fuselage, leaving the

exposed wood outside of the fuselage joining area.

Note

: This will be a little messy but the epoxy will clean up

easily and will allow you to obtain a strong joint of the stab

to the fuselage. Apply 30-minute epoxy to the top and

bottom of the exposed wood on the stab. Slowly work the

stab into the fuselage to a point 1" (25 mm) beyond the first

cut-line to appear on the other side of the fuselage. Since

the fit of the stab into the fuselage is tight, doing this will

push some of the epoxy back. Wipe away this excess epoxy.

Apply more epoxy to the exposed wood on the stab where

you pushed it past the center position and slowly move it

back into place after doing so. Carefully re-position the stab

into proper alignment. Using a paper towel, wipe away the

excess epoxy. Using a generous amount of denatured

alcohol on a paper towel, clean any epoxy residue from the

model, but do not allow an excess amount of alcohol to flow

into your joint. Also check the bottom of the fin slot on top of

the fuselage to make sure you do not have an excess

amount of epoxy in the area on top of the stab. The fin

needs to fit securely and properly into this area. Allow the

epoxy to thoroughly cure before moving the model.

❏

7. Trial fit the fin to the fuse. Use a triangle like the

Hobbico Builders Triangle (HCAR0480) to make sure the fin

is 90 degrees square to the stab. When satisfied that the fit

and alignment are correct, mark the location of the fuse

onto the fin. Carefully remove the MonoKote covering 1/8"

inside these lines using the same method used on the stab.

Apply a generous amount of 30-minute epoxy to the fin slot

sides and the top of the stab at the bottom of the slot. Insert

the fin into the slot and as with the stab remove any excess

epoxy and residue. Using your triangle, re-check for the

correct alignment in relation to the stab. Allow the epoxy to

completely cure before proceeding.

❏

8. To attach the elevators, drill a 3/32" (2.4mm) hole, 1/2"

(13mm) deep in the center of each hinge slot to allow the

CA to “wick” in. Follow up with a #11 blade to clean out the

slots and cut a strip of covering from the hinge slots in the

stab and elevators.

❏

9. Install the hinges into the stab and then test fit both of

the

elevators

. If the hinges don’t remain centered, stick a

pin through the middle of the hinge to hold it in position.

❏

10.

Remove any pins you may have inserted into the

hinges. Adjust the elevator so there is a small gap between the

LE of the elevator and the stab.The gap should be small — just

enough to see light through or to slip a piece of paper through.

❏

11. Apply six drops of thin CA to the top and bottom of

each hinge. Do not use CA accelerator. After the CA has

fully hardened, test the hinges by pulling on the elevators.

❏

12. To attach the

rudder

drill a 3/32" (2.4mm) hole, 1/2"

(13mm) deep in the center of each hinge slot to allow the

CA to “wick” in. Follow-up with a #11 blade to clean out the

slots and cut a strip of covering from the hinge slots in the

fin and rudder. Trial fit the hinges into the rudder and place

onto the fin. The gap should be small—just enough to see

light through or to slip a piece of paper through.

❏

13. Apply six drops of thin CA to each side of each hinge.

Do not use CA accelerator. After the CA has fully hardened,

test the hinges by pulling on the rudder.

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

17