15

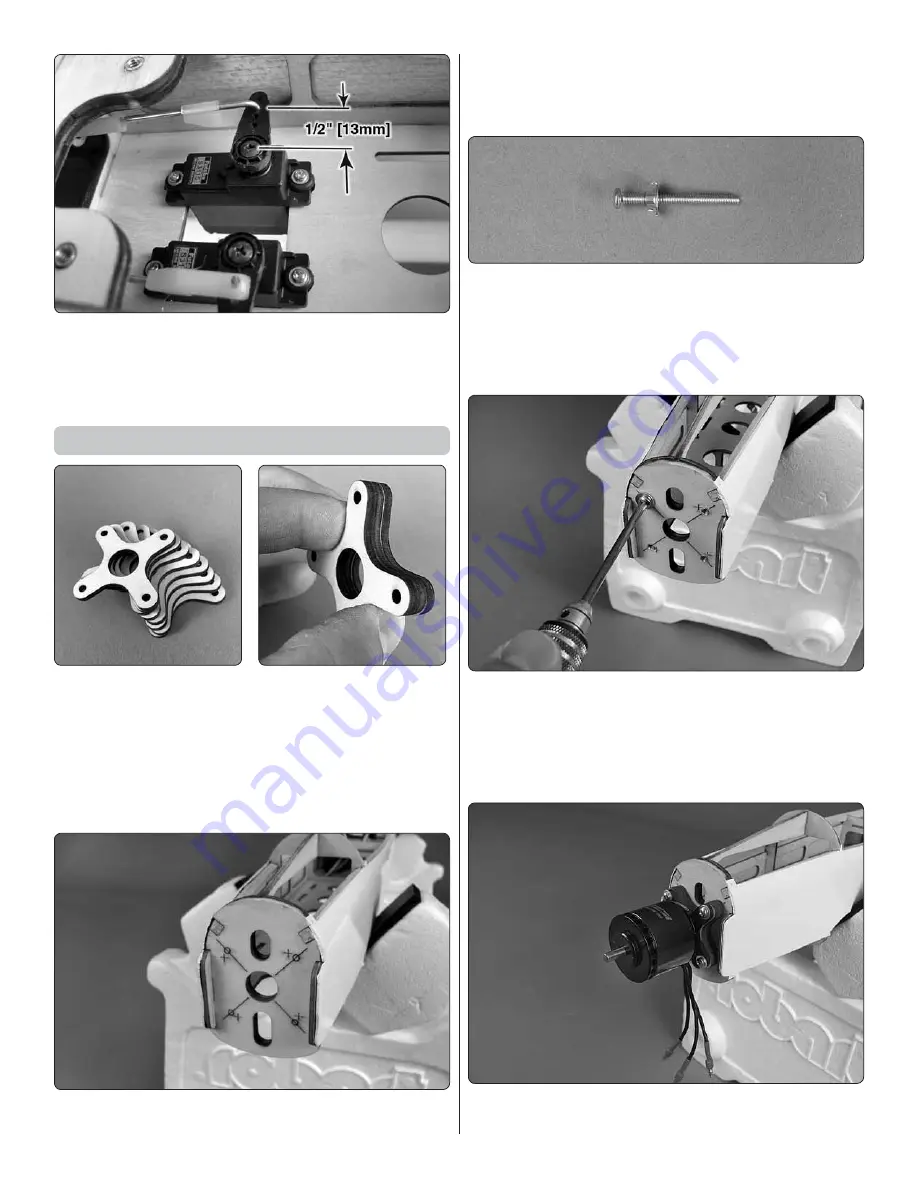

However, the clevis should connect to the second hole from

the base of the control horn and the 90 degree bend should

connect to the hole that is 1/2" [13mm] from the center of the

servo arm. A slight bend in the pushrod at the aft end will

prevent the pushrod from binding in the pushrod tube.

Install the Power System

❏

1. The Proud Bird includes eight plywood motor spacers

to accommodate different length motors. The recommended

O.S. .25 motor (OMA-3820-1200) requires the use of three

of these spacers to set the face of the prop adapter at the

correct length of 2-3/4" [70mm] from the fi rewall. The E-Flite

Power 25 1250kV motor does not need any spacers. Use

the spacers to properly space different model motors to the

correct distance from the fi rewall.

❏

2. The firewall has mounting hole locations for the

recommended O.S. .25 motor (“O” marks) and the E-Flite

Power 25 1250kV motor (“+” marks). Other motors may not

align with these marks and will require you to use the centering

lines on the fi rewall to mark the mounting hole locations for

your motor.

❏

3. 3x35mm screws are included for accommodating motors

requiring all eight motor spacers. If you are using less than eight

spacers, the screws can be cut shorter but this may not be a

necessary step. If you need to cut the screws, thread a blind

nut onto each screw before cutting them. Removing the blind

nut after the cut is made will straighten any damaged threads.

❏

4. Drill 5/32" [4mm] at the marks that match the motor

mounting hole pattern of your motor. We suggest starting with

small pilot holes to ensure accuracy. Use a motor mounting

screw and fl at washer to draw 3mm blind nuts tightly into the

holes you drilled. Apply a drop of glue to the back of each

blind nut to secure them in place.

❏

5. Mount your motor using the four 3x35mm motor mount

screws, four 3mm fl at washers and thread locking compound.