❏

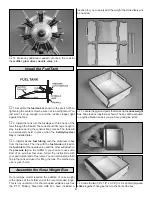

3. Fit the box cover to the box. Drill a 1/16" [1.6mm] hole

at the locations shown. Install and then remove a #2 x 3/8"

[9.5mm] sheet metal screw into each hole. Remove the

cover, and then apply a couple of drops of thin CA into the

holes in the box to harden the threads.

❏

4. Referring to the photo on the following page, locate

two 1/2" x 11/16" x 2-1/2" [13 x 18 x 64mm] hardwood

blocks. Position one of the blocks on the bottom of the

engine mount. The block should be resting against the

engine mount rail and the socket head cap screw that holds

the engine mount to the firewall. You will see that the block

cannot sit on the rail because one of the engine mount bolts

is extending through the rail. Mark the location of this screw

on the block. Where you have marked the block, cut away

enough of the wood to provide clearance for the screw,

allowing the block to rest against the rail. Repeat this for the

remaining block.

❏

5. Glue the blocks to the engine mount rails with CA. Drill

two 3/32" [2.4mm] holes through each of the blocks and the

engine mount. Drill a 1/8" [3mm] clearance hole through

the block only! Do not drill into the engine mount with the

1/8" [3mm] bit! Countersink the top of each of the holes you

have drilled so that the screw heads will sit flush with the top

of the hardwood blocks. Install a #4 x 1" [25mm] screw into

each of the four holes, making sure that the head of the screw

is flush or slightly below the top of the wood block.

❏

6. Place the box on top of the rails and between the

triangle stock located on the firewall. Drill four 1/16" [1.6mm]

holes through the inside of the box and into the hardwood

rails. Install and then remove a #2 x 3/8" [9.5mm] wood

screw into each of the holes. Remove the box. Apply a

couple of drops of thin CA into each of the holes to harden

the threads. Allow the glue to cure.

❏

7. Attach the box to the hardwood blocks. Secure the top

of the box with two #2 x 3/8" [9.5mm] screws and a two #2

washers. Fuelproof the box and rails.

That’s it for now for our box for lead. When you get the plane

ready for flight you will install the appropriate amount of

ballast to balance the plane. Hint: You may wish to consider

using the receiver battery for additional weight instead of

mounting the battery in the fuselage.

Did you know?...Over the years the PT-17 Military

Stearman has seen duty as a primary trainer, a

reconnaissance plane, a crop duster, and an air show

performer. In 1934 Argentina, Brazil and the Philippines

used Stearmans featuring wing-mounted .30 caliber

machine guns, a bomb rack between the landing struts and

a single machine gun for the rear!

❏

1. Install the tailwheel onto the tailwheel wire, securing it

with a 3/32" [2.4mm] wheel collar and a 4-40 set screw.

❏ ❏

2. Cut the 2" [51mm] axles to a length of 1-1/2"

[38mm]. Install the axle and axle nut onto both sides of the

landing gear. File a flat spot at the end of the axle as shown.

Install the Wheels

22