D 12. If the nylon bearing fits snugly into the groove,

you may use a few drops of thin CA to glue it in place.

If you have a loose fit, use thick CA or epoxy. DO

NOT GET GLUE INTO THE ENDS OF THE

NYLON BEARING TUBE!

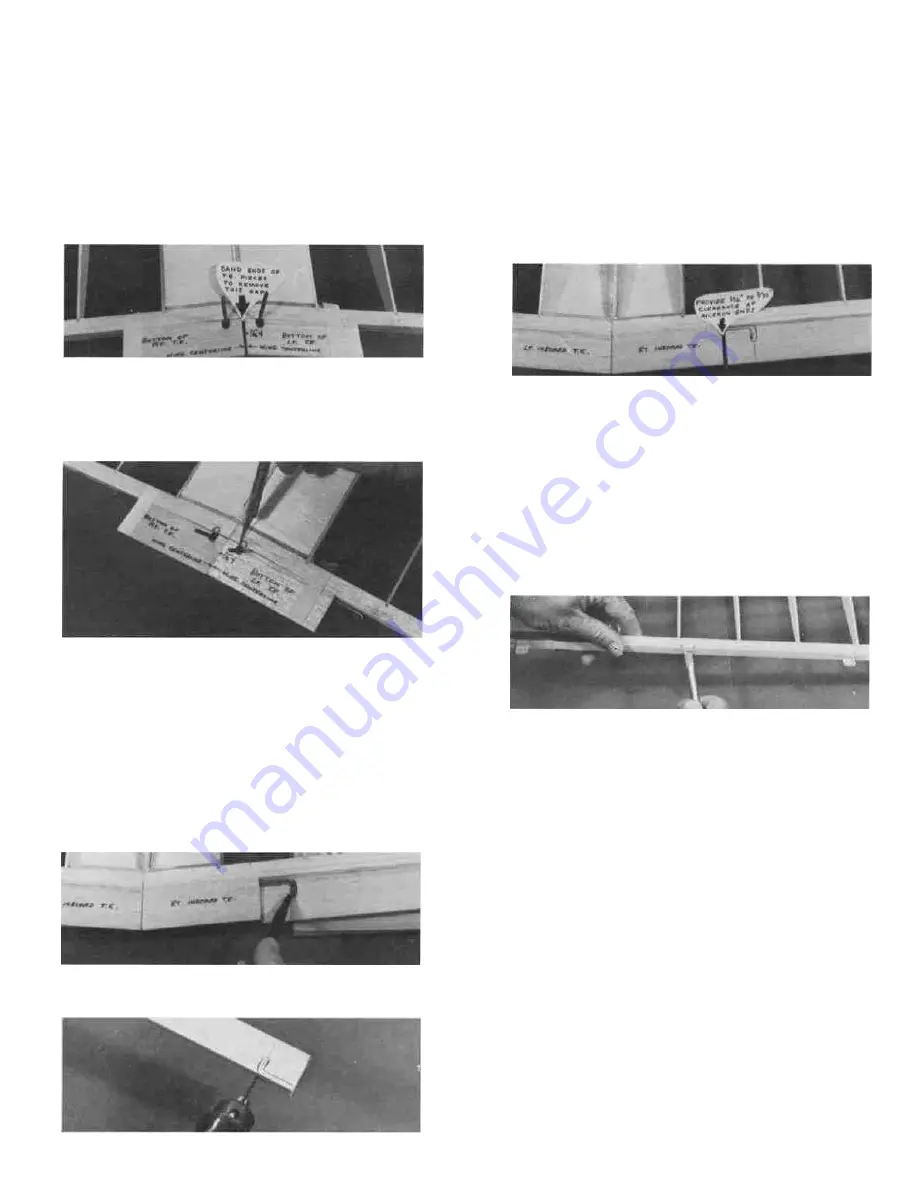

D 13. Turn the wing upside down, with the trailing

edge facing you, and temporarily position the inboard

T.E. pieces against the back edge of the wing. You

will notice the gap between the pieces, caused by the

dihedral angle. Sand the ends of the inboard T.E.

pieces so they come together without a gap.

D 14. With the T.E. pieces taped in their proper pos-

ition mark the location of the slots (where the

threaded portion comes out) on the back edge of the

wing as shown. Then remove the T.E. pieces and cut

slots in the back edge of the wing.

D 15. Glue the inboard T.E. pieces to the back of the

wing by carefully holding or taping the pieces in

place and applying thin CA in small drops along the

joints. Use care to avoid getting glue inside the nylon

bearings.

D 16. Mark a centerline all the way down the leading

edge of each aileron.

D 17. Hold the ailerons in place against the back

edge of the wing and mark the location where the

torque rods will enter the ailerons.

D 18. Drill a 3/32" hole in each aileron to accept the

torque rods.

D 19. Sand the leading edge of the ailerons to a "V"

shape as shown on the plan.

D 20. Groove the leading edge of each aileron to

accept the torque rods.

D 21. Trial fit the ailerons onto the torque rods.

D 22. Cut or sand a small amount off both ends of

the ailerons to provide about 1/16" to 3/32" of clear-

ance at each end. (Remember....the ailerons will be

covered with Super Monokote or other covering mat-

erial; therefore you must make some space at the

aileron ends so they don't tighten up after covering.)

D 23. Remove the ailerons and draw a centerline

down the back edge of the wing, in the aileron open-

ing.

D 24. Place the ailerons on the wing plan and mark

the locations of the hinges on the leading edge of the

ailerons. Now put the ailerons back in place on the

wing and transfer the hinge location marks to the

back edge of the wing.

D 25. Cut the hinge slots for the ailerons in the

same way that you did for the elevator and rudder.

D 26. Using 100 grit sandpaper, roughen the ends

of the torque rods that will go into the ailerons.

D 27. Trial fit the ailerons on the wing with the

hinges in place. DO NOT GLUE THE HINGES IN

UNTIL AFTER COVERING.

THE FOLLOWING INSTRUCTION

PHOTOS SHOW THE "B" WING (WITH

AILERONS), BUT THE PRINCIPLES APPLY

TO BOTH "A" AND "B" WINGS.

INSTALL THE WING TIPS

D 1. Sand the wing tips smooth and flat with your

T-bar and 100 grit sandpaper.

D 2. Find the two tapered balsa pieces that are

11-3/8" long. These are the wing tips.

D 3. Holding the wing and wing tip on a flat surface

covered with waxed paper (the narrow edge of the

tapered piece goes down), apply thin CA glue to the

joint.

(See photo, top of next page.)

21