D 7. Do the sides next. Tack and seal the edges,

vent at the nose and tail and finish the job. Trim the

covering flush with the bottom and flush at the top

also.

D 8. Cover the top of the fuselage. Do this in two

parts, the rear and the front of the fuselage on either

side of the wing saddle area. Tack and seal the edges.

Finish the top area with the heat gun and rag. Bring

the top covering down 1/4 inch over the sides. Trim

and seal it.

D 9. Carefully cut away the covering from the fuse

sides where the wing hold down dowels will be in-

serted. Smear 5-minute epoxy on the dowels and in-

sert them so they stick out the same on both sides.

Wipe off the excess epoxy with a tissue. After the

epoxy sets you may either cover or paint the exposed

ends of the dowels.

COVER THE WING

D 10. Cover the tips first with 3" x 12" pieces of

covering material. Iron the covering down to the flat

ends of the tips, then pull and stretch the covering

around the comers while heating with the iron. Trim

off the excess.

D 11. Now cover the bottom of one wing panel, over-

lapping the center of the wing by at least 1/4". First

iron the covering down to the center of the wing and

at the tip. Next, seal the covering to the trailing edge

and the leading edge (the covering should wrap at

least halfway around the leading edge). Once sealed

all the way around, you may shrink the covering tight

with a heat gun. Hold the heat gun a few inches away

from the covering, and keeping it moving, so you

don't melt through. Finally, use the iron to seal the

covering to the spars.

D 12. Cover the bottom of the other wing panel in

the same manner as above.

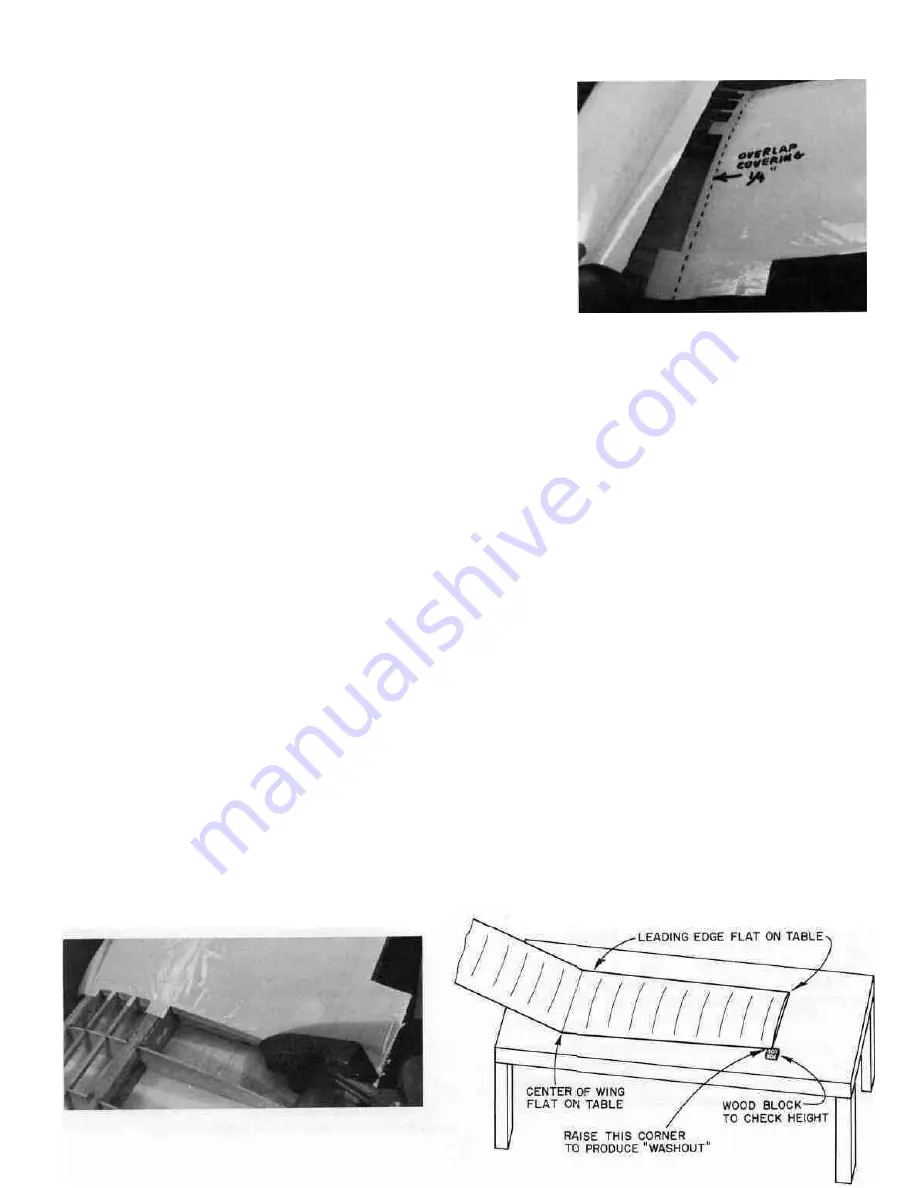

SPECIAL NOTE: When covering the top of

the wing, make sure the top covering overlaps the

bottom covering by at least 1/4" at the leading edge.

D 13. Next, cover the top of one of the wing panels.

At the center of the wing, allow the covering to over-

lap the center ribs by about 1/2" . Slit the covering

at the spars, then iron it down to the side of the

center rib, as shown in the following photograph.

D 14. Cover the top of the other wing panel making

sure you overlap the covering at least 1/2" at the

center.

SPECIAL NOTE: The above instructions for

covering told you how to cover with one color. You

can get a little fancier and use a second color for trim

like we did on ours on the box lid. If you use two

colors, cover with the lightest color first, like the

white on ours. The white was put on the fuselage

side about halfway down. Then the red was cut with

a straight edge, tacked and sealed at the red/white

seam and then tacked and sealed at the bottom. A

heat gun was then used to finish. The rest of the

plane was covered totally in white and then pieces

of Super MonoKote red were cut to shape and adhered

with a heat gun and rag to the white. Just the top

of the wings have the red trim. You usually want the

top of the wings to look different than the bottom so

you can tell what the airplane is doing in the air.

After the red trim was added, we put

some of our 1/16" black striping tape along the red

for more trim. We used gray Super MonoKote for the

windows, masked them off and spray painted black

around the edges to give the windows some depth.

You can follow our trim scheme or create your own!

Use your imagination and have fun creating your

very own PT40.

ADD "WASHOUT" AT THE WING TIPS

SPECIAL NOTE: One important flying

characteristic of the PT40 is its ability to recover

"hands-off" from a steeply banked turn. This is made

possible by building the wing with DIHEDRAL and

WASHOUT. You will add washout to each wingtip

by intentionally warping the wing panels, so that

the trailing edge will be higher than the leading

edge at each wingtip. Here's how to do it...

31