D 11. Cut a hole in the center of the fuse top, about

2" behind the wing saddle, and glue in a 2-1/2" length

of fuel tubing to serve as an antenna exit (see the

fuse plan).

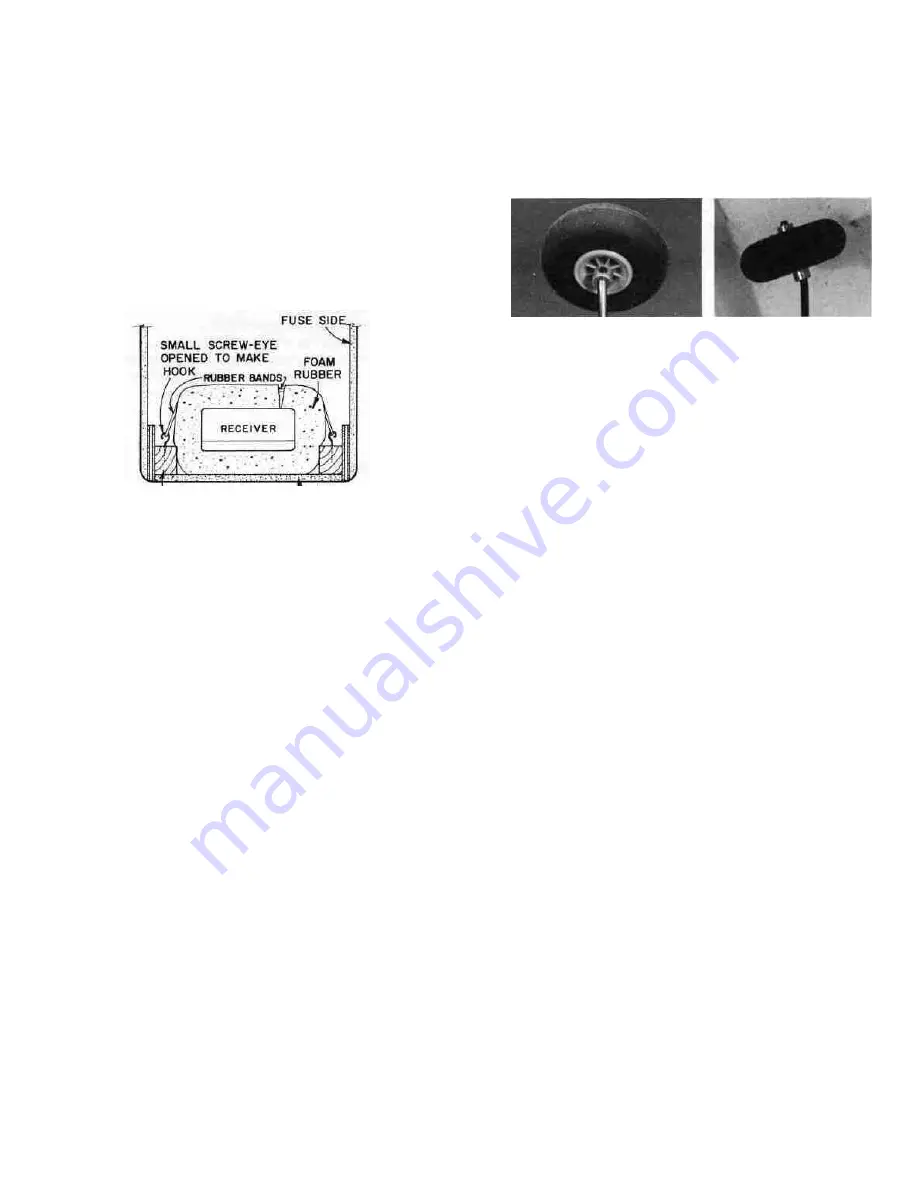

D 12. Wrap foam rubber around the receiver and

hold the foam in place with a couple of rubber bands.

Now you must attach the receiver to the fuselage in

such a way that it does not move around, but at the

same time it must be cushioned from vibration. A

good method for accomplishing this is to secure two

hooks down in the bottom corners of the fuselage,

and rubber band the receiver down.

RECEIVER (AND

BATTERY) MOUNTING

-BASSWOOD BLOCK BOTTOM

(SCRAP FROM WING SPAR)

D 13. Wrap the battery pack in foam rubber, place

it in a plastic bag, and close it with a couple of small

rubber bands. Now secure the battery pack in the

bottom of the fuel tank compartment in the same

manner as you did the receiver. Also place a piece of

foam rubber between F-l and the battery pack.

D 14. From scraps of plastic, make the "antenna st-

rain relief and the "antenna clip" (unless your radio

system includes these). Pass the receiver antenna

wire through the holes in the plastic strain relief

piece, then through the antenna exit tube. Adjust

the position of the strain relief such that the portion

of the antenna inside the fuselage remains loose,

even when you pull on the end of the antenna. Now

attach the end of the antenna to the top of the fin

using your antenna clip, a small rubber band and a

pin. Note: The receiver antenna is "tuned" for the

frequency on which the radio will operate, so do not

cut off any of its length. Just allow the excess to trail

behind.

D 15. Plug the servo wires into the receiver and hook

up the battery and switch (refer to your radio instruc-

tion manual for guidance).

D 16. The fuse top view shows a piece of 1/16" wire

passing through the switch and out the side of the

fuse. This enables you to switch the receiver on and

off without removing the wing. Install a remote on/off

switch pushrod similar to the one shown.

D 17. Lay the fuel tank in place on top of the battery

pack. Run a piece of fuel line tubing from the fuel

pick-up ("klunk") through the hole in F-l to the fit-

ting on the carburetor. Run a second piece of tubing

from the tank "vent" through the hole in F-l to the

pressure tap fitting on the muffler. To prevent fuel

foaming the tank must be isolated from direct con-

tact with the fuselage, so add foam rubber in front

and on top of the tank before replacing the hatch.

D 18. Install the wheels on the main landing gear

and nose gear using 5/32" wheel collars on both sides

of each wheel

SPECIAL NOTE: If you plan to f l y from a

concrete, blacktop or smooth grass field, use 2-1/2"

diameter main wheels and a 2-1/4" diameter nose

wheel. However, if the field you will be flying from

is rough or has fairly long grass, we recommend using

2-3/4" main wheels and a 2-1/2" nose wheel. In either

case, you should bend the main landing gear if neces-

sary so the model sits level or slightly nose down

when at rest.

D 19. Install the proper size propeller for your engine

(see your engine instruction manual), and a 2-1/4"

diameter spinner. Note: If you choose not to use a

spinner, you should ( for safety reasons) use a rounded

"acorn"-type prop nut to hold the propeller on.

SPECIAL NOTES ON PROPELLERS: Vib-

ration is the main enemy of the electronic and

mechanical parts in an R/C airplane, and an out-of-

balance propeller is the primary source of the hard

vibrations that cause problems. For only a few dollars

you may purchase a prop balancer. We highly recom-

mend that you do so, and carefully balance each prop-

eller before bolting it on your airplane.

Always use propellers that are in perfect shape.

Discard any prop with nicks, scratches, splits or

cracks or any sign of wear and damage. Never repair

or alter a prop (propeller).

Paint the prop tips white so you can see the

ends when the prop is spinning (this is especially

important if you are using one of the black fiberglass-

filled nylon props).

Install the prop with the curved side facing

forward. Securely tighten the prop nut. Inspect the

prop and re-tighten the nut after every few flights.

If you install a spinner, make sure the edges of the

spinner do not touch the prop blades.

D 20. While standing behind the model, adjust

the servo reversing switches on your transmitter so

the elevator, rudder, throttle (and ailerons) move in

the correct directions as follows:

33