The 4-Channel version has more ability to per-

form acrobatic maneuvers, but is more difficult to

build and its self-recovery characteristics are not

quite as good. If you already have some R/C flying

experience and are ready to move up to an airplane

that is more maneuverable, you may choose to build

your PT40 as a 4-Channel airplane with Wing B.

BUILD THE FUSELAGE SIDES

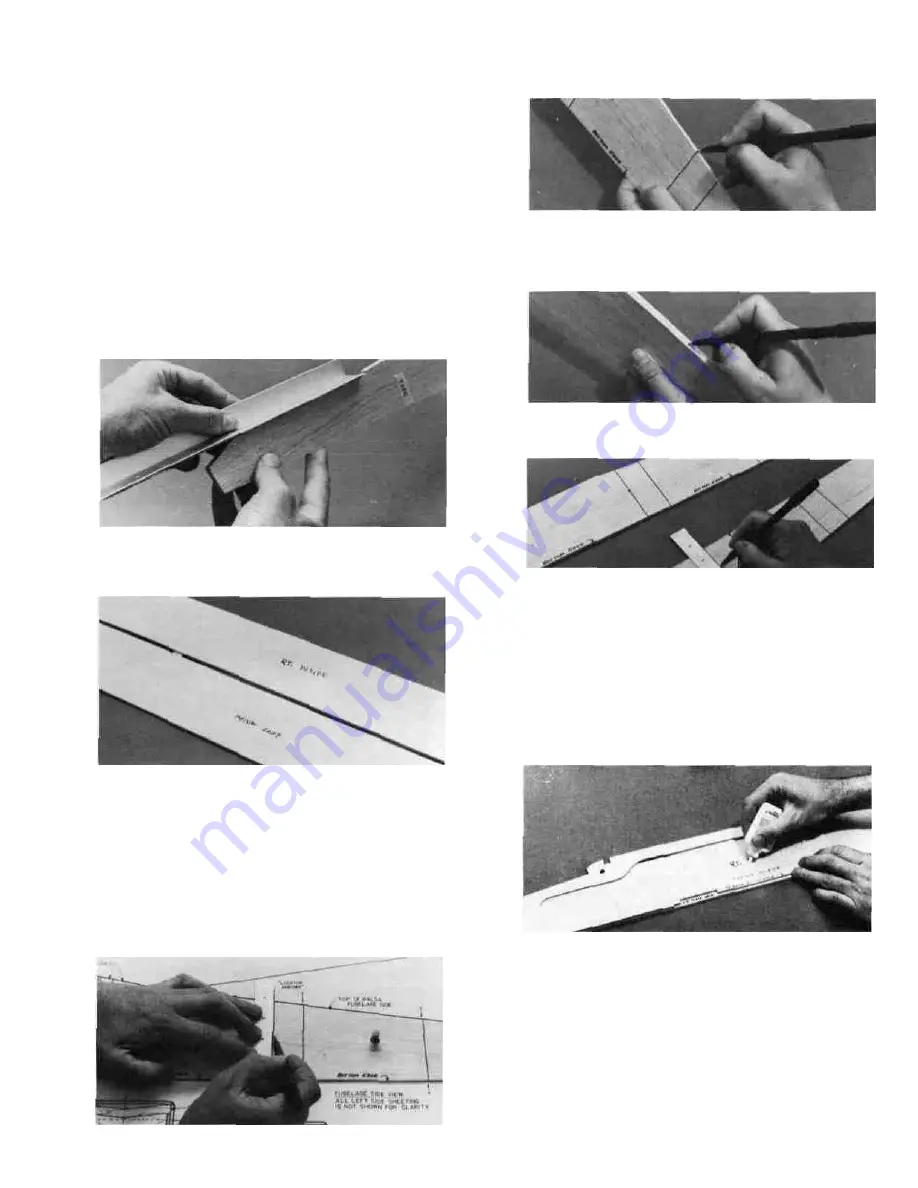

D 1. Take the two large 1/8" balsa fuselage sides

and put them together. Carefully line them up along

the bottom edge and the front. Tape them together

with a few pieces of masking tape along the bottom

edge to prevent them from moving. Now examine the

other edges to make sure the two fuselage sides are

exactly the same all around. If not, use a T-bar sander

with 100 grit sandpaper to lightly sand the edges to

match.

D 2. Now, with the tape still in place along the

bottom edge, let the two sides fall open and write

"Rt inside" and "Left inside" as shown here.

D 3. Tape the fuselage plan to your building sur-

face.

D 4. Lay the right fuse (fuselage) side on the plan,

and carefully position it so the bottom edge and the

nose line up with the plan. Insert a few pins or tape

to hold it in place.

D 5. Using the "locator arrows", a straightedge

and a pen, draw six vertical lines on the fuse side as

shown. Press lightly to avoid damaging the balsa.

D 8. Now draw lines on the left inside fuse side,

using the edge marks and a straight edge.

D 6. Remove the fuse side from the plan and make

small marks on the top and bottom edges, where the

lines end.

D 7. Put the two fuse sides together (inside to in-

side), and line them up carefully. While holding them

together, transfer the edge marks over to the left fuse

side edges as shown here.

D 9. Lay the large 1/8" ply fuse doubler on the right

inside fuse side and position it to line up at the nose

and bottom edge. The part of the doubler which is

behind the L.G. plate area must be exactly 1/8"

above the bottom edge of the fuse side. Use a piece

of 1/8" balsa (such as the "windshield" piece) to check

this spacing. When you are satisfied that the doubler

is correctly lined up, apply thin CA glue all around

the edges while holding the doubler in place. Use

enough glue to make sure it flows under the plywood

to make a good bond.

D 10. Position the upper and lower "lock plates" and

the stab saddle doublers on the right fuse side, using

the vertical guidelines previously drawn. The upper

lock plates and stab saddle doubler must be even with

the top edge of the fuse side. The three lower

lock plates must be positioned 1/8" above the bot-

tom edge of the fuse side. Use a piece of 1/8" balsa

as a spacer to aid in correct positioning of the bottom

lock plates. Glue these parts in place with thin CA.

(See photo on next page.)