16

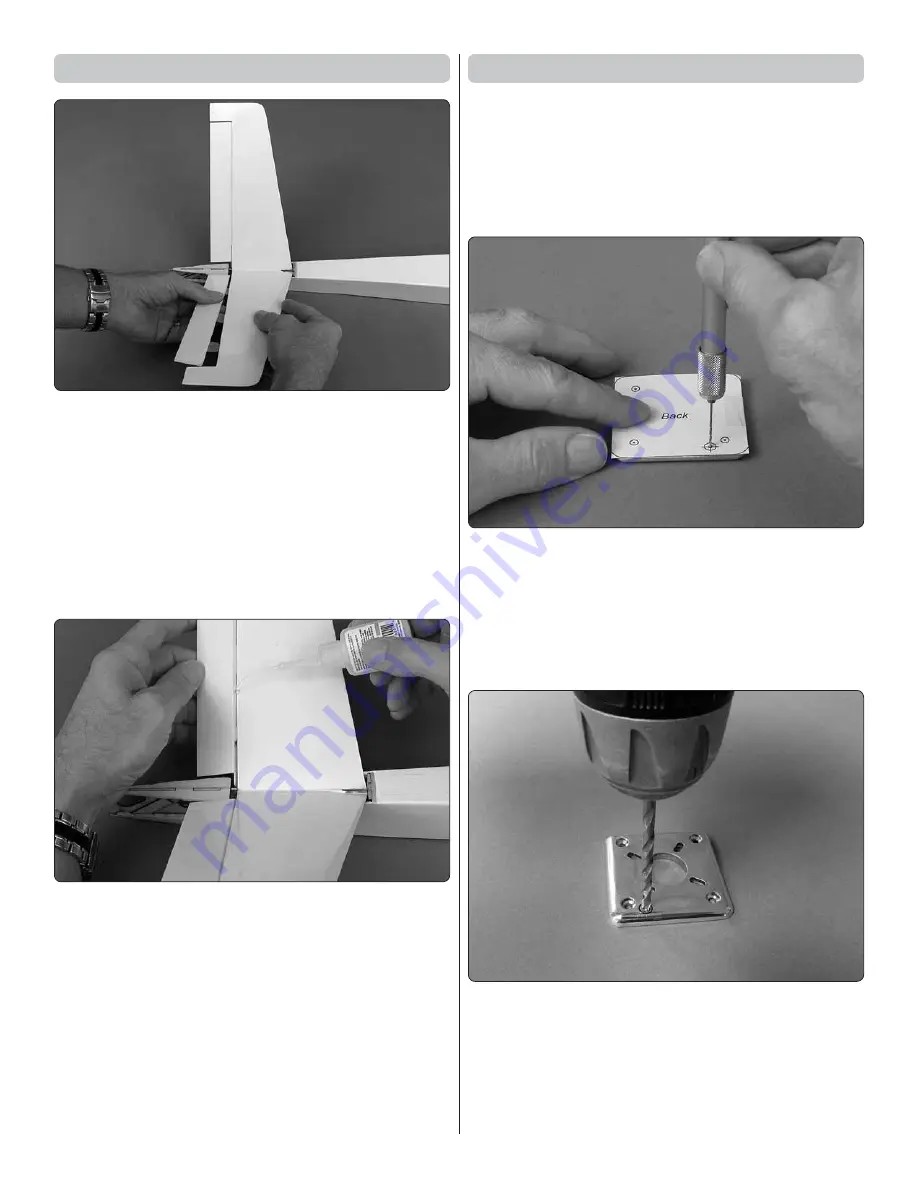

Hinge the Ruddervators

❏

1. Install the ruddervator pushrods if they aren’t already

installed. Connect the balls on the ruddervator torque rods

to the ball links on the pushrods, then fi t the ruddervators

to the V-tail with the hinges—be certain the hinges remain

centered as they go in.

❏

2. Connect the ruddervator servos to your receiver and a

battery so you can operate the servos and ruddervators with

your transmitter. Make sure everything moves smoothly and

operates correctly and that the pushrods are the correct

length so the ruddervators will be centered when the servos

are centered. Make any adjustments necessary.

❏

3. Permanently join the ruddervators with the torque

rods to the V-tail by securely gluing in the hinges with 6

– 8 drops of thin CA on both sides of each hinge. Allow

time between drops so the CA soaks into the hinge slots

instead of running down the hinge gap.

❏

4. Any excess CA or CA “fog” can be removed with a

small paper towel square and debonder.

❏

5. Pull hard on each ruddervator to make sure the

hinges are secure.

The wood tail covers will be added after it has been

determined whether or not any ballast is required in

the tail to achieve the correct C.G.

Mount the Engine

Installation of both a sport setup with an O.S. Max .55AX

with the included back plate mount and the Jett QJ-1

engine for AMA 426 with the Jett back plate mount are

illustrated. Follow the instructions for the setup you will

be using.

SPORT ENGINE WITH INCLUDED BACKPLATE MOUNT:

❏

1. If using the O.S. .46 or .55AX (or most other engines

that will have the carburetor arm on the bottom with the

engine mounted on its side), cut the back plate template

labeled “

Back

” from the back of the manual. Tape the

template to the

back

of the back plate mount, then mark

the throttle pushrod hole using a small drill. (This hole also

aligns with the hole for the throttle cut wire in the Jett

Engineering back plate mount.)

❏

2. Drill a 1/16" [1.6mm] hole at the mark, then enlarge

the hole with a 3/16" [4.8mm] drill.

❏

3. Run a 6-32 tap down through the blind nuts in the

fi rewall to clean up any epoxy leftover from the fi llet inside.

If the tap won’t go through, drill out the obstruction with a

#36 (or 7/64" [2.8mm]) drill, then run the tap.