13

We’re going to instruct you to center the servos and

adjust the pushrods now, but this could be done later

during fi nal setup if you prefer.

❏

3. Temporarily connect the servos to your receiver with a

battery and a switch so you can move the servos with your

transmitter. Turn on your transmitter and make sure the trims

are centered and turn on the receiver.

90˚

90˚

NO

NO

YES

CUT OFF THE

UNUSED ARMS

GREAT PLANES

LARGE-SCALE ARM

❏

4. Mount your servo arms to the servos—if using the

recommended Great Planes large-scale servo arms,

position the square plastic inserts so the servo arms will be

90-degrees to the servo. If using the standard servo arms that

came with your servos, fi nd the arm that will be 90-degrees

to the servo and cut off the remaining unused arms.

❏

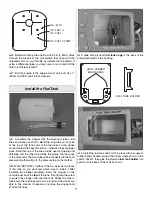

5. Read the following

Expert Tip

about how to solder

pushrods, then make the pushrods and connect the rudder

and elevator with the pushrods and control horns as shown

in the photos.

IMPORTANT:

Be certain you are soldering the

solder clevises

onto the non-threaded end of the pushrods

and threading the

threaded clevises

onto the threaded end

of the pushrods. Sometimes modelers mistake unthreaded

clevises for threaded clevises.

Note:

Make sure the horns

are-mounted over the hardwood plates built into each control

surface and are positioned as thown in the sketch at step 6.

And drill 1/16" [1.6mm] holes for the #2 x 1/2" [12.7mm] Phillips

horn mounting screws. Don’t forget the important procedure

of installing, then removing the screws and hardening the

holes with thin CA.

HOW TO SOLDER

❏

A. Use denatured alcohol or other solvent to thoroughly

clean the pushrod. Roughen the end of the pushrod with

coarse sandpaper where it is to be soldered.

❏

B. Apply a few drops of soldering fl ux to the end of

the pushrod, then use a soldering iron or a torch to heat

it. “Tin” the heated area with

silver solder

(Stay Brite,

STAR2000) by applying the solder to the end. The heat of

the pushrod should melt the solder—not the fl ame of the

torch or soldering iron—thus allowing the solder to fl ow.

The end of the wire should be coated with solder all the

way around.

❏

C. Place the clevis on the end of the pushrod. Add

another drop of fl ux, then heat and add solder. The same

as before, the heat of the parts being soldered should

melt the solder, thus allowing it to fl ow. Allow the joint to

cool naturally without disturbing. Avoid excess blobs, but

make certain the joint is thoroughly soldered. The solder

should be shiny, not rough. If necessary, reheat the joint

and allow to cool.

❏

D. Immediately after the solder has solidifi ed, but while

it is still hot, use a cloth to quickly wipe off the fl ux before

it hardens.

Important:

After the joint cools, coat with oil

to prevent rust.

Note:

Do not use the acid fl ux that comes

with silver solder for electrical soldering.

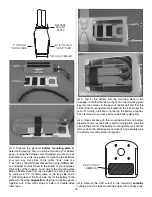

This is what a properly soldered clevis looks like—shiny

solder with good fl ow, no blobs, fl ux removed.

“JAM” NUT

SILICONE RETAINER

❏

6. After all the pushrods have been made and the elevator

and rudder connected, tighten the 4-40 “jam” nuts to

the threaded clevises and install silicone retainers on all

the clevises.

Summary of Contents for Reactor ARF

Page 36: ......