22

❏

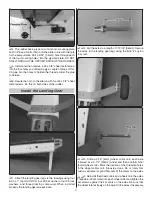

9. Put the cowl back onto the fuselage. You will need to

make some clearance in the cowl for the spark plug lead.

Make fi nal adjustments to the cowl as needed. When you

have fi nished, mount the cowl with the two 6-32 x ¾" [19mm]

socket head cap screws, #6 lock washers and #6 fl at washers.

Secure the bottom of the cowl with 6-32 x 1" [25mm] socket

head cap screws, #6 lock washers and #6 fl at washers. Now

that you have cut open the cowl for the engine and muffl er

clearance you will be able to insert the lower bolts into the

lower mounting holes in the bottom of the cowl.

❏

10. Cut two holes in the bottom of the fuselage sized to

fi t your fuel line. Feed the vent and fi ll line through the holes.

Install the fuel plug in the fuel line.

❏

11. Rotate the prop shaft until the engine is on compression

(the piston is at the top of the cylinder). Slide your prop onto

the engine shaft. (You may need to drill the center of the prop

to fi t the engine). Once the prop fi ts the shaft set your prop

somewhere near the 1 o’clock and 2 o’clock position. This

is the position most modelers prefer. If you prefer a different

position set the prop there. Make a reference mark on the prop

that aligns with one of the holes in the drive washer.

❏

12. Drill the prop for the bolt holes required for your engine.

Many manufacturers sell a drill gauge guide specifi cally for

this purpose (DLEQ0551 for the DLE 55). If you do not own

a drill guide you can also use the prop washer as your guide.

For accuracy it is best to use a drill press when drilling the

holes. After drilling the holes be sure to check that the prop

matches the drive washer and that it is positioned correctly.

Summary of Contents for Revolver 50cc

Page 32: ...GPMA1425 Mnl...