❏

4. Install the fuel tank so the neck fits through the hole in

the firewall. Be certain that you have installed the tank so the

vent tube inside the tank is pointing upward. Use a couple of

#64 rubber bands (not included) to hold the tank to the tank

floor. Note: There may be a little resistance installing the tank

at the point when it is at an angle pointing toward the top of the

fuselage, but with a little “persuasion” it will slide into position.

❏

5. Test fit the rudder servo and both elevator servos in the

1/8" [3mm] plywood aft servo tray. If necessary, enlarge the

opening to accommodate the servos. Drill 1/16" holes in the

tray for mounting the servos, then add a few drops of thin CA

to the holes and allow to harden. Don't mount the servos into

the tray until instructed to do so.

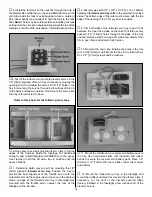

Refer to this photo for the following four steps.

❏

6. Use epoxy to securely glue the aft servo tray to the top

edges of the crutches inside the fuselage. For additional

strength, add milled fiberglass (GPMR6165) to the epoxy.

Use clamps to hold the aft servo tray in position until the

epoxy hardens.

❏

7. Determine which way you will be mounting the 1/8"

[3mm] plywood forward servo tray. Position the tray to

provide the best alignment of the throttle servo with the

carburetor arm on the engine. As can be seen in the photo at

step 6 on page 21 the forward servo tray in this model was

mounted with the throttle servo nearest the rear of the

fuselage on the left side.

❏

8. Securely glue both 1/4" x 3/8" x 6-1/4" [6 x 10 x 160mm]

hardwood forward servo tray rails to the plywood inner fuse

sides. The bottom edge of the rails must be even with the top

edge of the opening in the 1/16" ply inner fuse sides.

❏

9. Trim both sides of the forward servo tray to get it to fit

between the inner fuse sides on the rails. Drill three evenly

spaced 1/16" [1.6mm] holes through both sides of the tray

and the rails (see step 6 on page 21). Add a few drops of thin

CA to each hole and allow to fully harden.

❏

10. Remove the servo tray. Enlarge the holes in the tray

with a 3/32" [2.4mm] drill. Mount the tray to the rails with six

#2 x 1/2" [13mm] screws and #2 washers.

❏

11. Mount the throttle servo, receiver and battery pack to

the tray. Use hard balsa sticks (not included) and rubber

bands to secure the receiver and battery pack. Place 1/4"

[6mm] or 1/2" [13mm] R/C foam rubber under the receiver

and battery.

❏

12. Mount the forward servo tray in the fuselage and

mount the rudder and elevator servos to the aft servo tray. If

necessary, cut the front of the elevator pushrod tubes

(factory installed in the fuselage) a few inches short of the

elevator servos.

16