❏

1. Cut the covering from the hole in both sides of the rudder

for the 6-32 x 1-1/2" [38mm] threaded control rod. Temporarily

thread the rod into the rudder until it is centered. (A hemostat

was used to thread the control rod into the rudder.)

❏

2. Use a #36 (or 7/64" [2.8mm]) drill to enlarge the hole in

both nylon torque rod horns. Use a 6-32 tap to make threads

in the horns. Screw the horns onto the threaded rod on the

rudder until the top of the horns are even with the ends of the

rod. (The horns can be seen in photos on page 18.)

❏

3. Test fit the rudder to the fin with the hinges. If

necessary, enlarge the holes in the back of the fuselage so

the torque rod horns will not contact the edges when the

rudder is moved back and forth.

❏

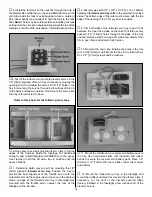

4. Slip a small copper tube (also called a “swage”)and a

threaded brass coupler with a clevis about 6" [150mm] onto

one end of the braided steel rudder pull/pull cable.

❏

5. Insert the end of the cable back down through the

swage, then loop it around and thread it back up through the

swage (as indicated by the dashed line in the photo).

❏

6. Pull the short end of the cable tight through the swage

until the loop “ends” at the swage.

❏

7. Pull the long end of the cable through the swage,

decreasing the loop around the threaded brass coupler until it

is approximately 3/8" [9mm] long. Use pliers to tightly squish

the swage, then cut the excess cable at the end of the swage.

❏

8. Connect another threaded brass coupler to the other

end of the cable the same way, then cut the cable into two

equal lengths.

Hook Up the Rudder

17