the pushrod into the pushrod tube, then bend it as

necessary to connect to the steering arm. Mount a screw-

lock connector to the rudder servo arm with a nylon retainer.

Temporarily fit the pushrod into the connector.

❏

9. Make a brace for the front of the tail wheel pushrod

tube from the 1/4" x 1/2" x 6" [6 x 13 x 150mm] balsa stick.

Drill a 3/16" [4.8mm] hole through the brace, then slip the

brace over the tail steering pushrod tube. Glue the brace in

the fuse so the pushrod aligns with the screw-lock connector

on the rudder servo. Glue the pushrod tube to the brace.

Center the tail wheel, then secure the pushrod to the screw-

lock connector with a 4-40 x 1/8" [3.2mm] screw.

❏

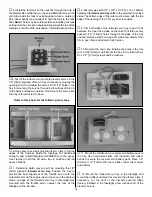

1. Mount the engine mount to the firewall with four 8-32

x 1" [25mm] SHCS, #8 lock washers and #8 flat washers,

but do not tighten the screws. Adjust the mount to fit your

engine and tighten the screws.

❏

2. Mount the back plate of the spinner to the engine.

Position the engine on the mount so the back plate will be 5-

7/8" [150mm] from the firewall. Temporarily hold the engine

to the mount with a small “C”-clamp. Use a Great Planes

Dead Center

™

Hole Locator (GPMR8130-shown in the

photo) or another method to mark the locations of the holes

for mounting the engine.

❏

3. Remove the engine mount from the firewall. Drill #29

(or 9/64" [3.6mm]) holes through the mount at the marks.

Tap 8-32 threads into the holes. Mount the engine mount to

the fuse, then mount the engine to the mount with 8-32 x 1"

[25mm] screws and #8 lock washers. Center the mount on

the vertical line on the firewall, then tighten the bolts that

hold the mount.

❏

4. Drill a 3/16" [4.8mm] hole through the firewall for the

throttle pushrod in alignment with the carburetor arm.

❏

5. Cut the 3/16" x 12" [4.8 x 300mm] pushrod tube to the

correct length, then roughen one end and guide it through

the hole you drilled. Thread a nylon clevis twenty full turns

onto the 2-56 x 18" [460mm] pushrod. Bend the front of the

pushrod as necessary, then connect the clevis on the

pushrod to the carb arm.

❏

6. Cut the other end of the pushrod to the correct length,

then bend it as necessary to connect to a screw lock

connector on the throttle servo arm. Similar to the brace

used for the tail wheel steering pushrod tube, make a brace

for the throttle pushrod tube from the piece of leftover

1/4" x 1/2" [6 x 13mm] balsa stick and glue it into position.

Mount the Engine

21