over the plan. Place a 1/4” x 1/4” x 24” auxiliary spar and a

1/8” x 1/4” x 24” rear spar in position as well. Without using

any glue, position a W-3 rib (with the single doubler to the

inside of the panel) onto the spars and LE sheeting. Add

another W-3 rib (without any doublers) to the spars at the tip

end of the panel.

❏ ❏

5. Pin the two ribs and spars in position. Still without

using glue, add the W-3 rib (with both doublers), two plain

W-3 ribs and two W-4 ribs.

❏ ❏

6. From a 1/16” x 3” x 12” balsa sheet cut two 12” strips

1-3/8” wide. Save the second one for the other wing. Slide

one of the strips under the trailing edge of the panel. The

strip should butt against the forward edge of the notch in the

W-3 ribs. Pin it in position. Trim the outboard end flush with

W-3. Pin the cut off piece under the outboard W-3.

❏ ❏

7. Still without using any glue, install the 1/4” x 1/4” x

30” top auxiliary spars, 1/2” x 3/8” x 36” main spar and 1/8”

x 1/4” x 30” aft spar.

Do not trim the spars at the tip end!

Allow them to protrude past the last rib.

❏ ❏

8. Starting with the W-3 rib with

two doublers

(

not the

root rib

), glue all ribs (except the root rib) in position with

thin CA. Work toward the tip, checking that each rib is

vertical with a builders square or triangle.

❏ ❏

9. Position the 1/8” die-cut ply

dihedral gauge (DG)

against the

inboard face of the root rib

and angle the rib

to match the angle of the gauge. Check that the rib is

straight (chordwise) with a straightedge. Once satisfied that

the angle is correct along the length of the rib, glue it in

place with thin CA. Check your work to be sure everything

is properly glued.

❏ ❏

10. Glue the two pieces of the 3/32” die-cut balsa

wing

tip (W5A AND W5B)

together and sand the joint smooth.

Slide the tip over the spars and tilt it up to fit against the top

spars. When satisfied with the fit, glue the tip in place. All of

the spars may now be roughly trimmed to size; sanding will

be done later.

❏ ❏

11. From 1/16” x 3/4” balsa

sub leading edge

stock cut

a 24-1/2” long piece. Glue this piece to the LE of all ribs.

Sand the top edge of the sub leading edge to match the

angle of the airfoil.

12

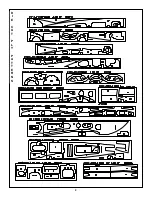

Summary of Contents for SlowPoke Sport 40

Page 4: ...4 D I E C U T P L Y P A T T E R N S...

Page 5: ...5 Use this drawing or photocopy it and use the copy to design your trim scheme...

Page 29: ...B C...

Page 30: ...D A...