❏

6. This fuselage has a 1/8" [3.2mm] balsa side and a 1/8"

[3.2mm] ply doubler. There is also a 1/4" x 1/4" [6.4 x

6.4mm] balsa filler stick glued to the bottom sheeting and

resting on the edge of the ply doubler. Cut the stick and

fuselage side down to the ply doubler. Do not cut deeper

than 1/2" [12.7mm], the thickness of the mounting block.

❏

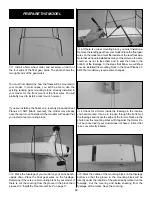

7. After cutting down to the ply doubler, the mounting

block will likely protrude from the bottom of the fuselage

slightly; in our case it was 1/8". Trim the fuse side and ply

doubler until the mounting block is flush with the bottom of

the fuselage.

❏

8. Using epoxy, glue the 1/2" x 3/4" x 1" [12.7 x 19 x

25.4mm] support blocks to the fuselage sides as shown in

the photo. If your model does not have a former that the

mounting block can be glued to, you should make longer

support blocks to provide additional support.

❏

9. Using epoxy, glue the mounting block to the support

blocks, fuselage sides and former. Glue a filler strip to the

mounting block, if needed, so that the bottom sheeting can

be glued to the mounting block.

❏

10. Use the covering that you saved to cover the mounting

block and the fuselage sides. There may not be enough

covering, so do the visible part of the fuselage sides first.

Leftover Cub Yellow MonoKote

®

can be used on the bottom.

If the landing gear is still installed on the model, remove it.

Set the parts aside where you won’t misplace them.

❏

1. Install four nylon landing gear straps on each float

using eight #4 x 1/2" [12.7mm] sheet metal screws and

eight #4 flat washers. The side of the straps should be

Install the Float Gear Wires

INSTALL THE FLOATS

11