Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

If you have not flown this type of model before, we

recommend that you get the assistance of an

experienced pilot in your R/C club for your first flights.

You’ll learn faster and avoid risking your model before you

are truly ready to fly it. Your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

In addition to joining an R/C club, we strongly recommend you

join the AMA (Academy of Model Aeronautics). AMA

membership is required to fly at AMA sanctioned clubs. There

are over 2,500 AMA chartered clubs across the country. Among

other benefits, the AMA provides insurance to its members who

fly at sanctioned sites and events. Additionally, training

programs and instructors are available at AMA club sites to help

you get started the right way. Contact the AMA at the address or

toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

For steering your model on the water, a water rudder will be

installed on the right float. The water rudder can be connected

to the aircraft rudder by a pushrod, or a servo can be installed

inside the float. All parts required for either type installation are

included with this kit (servo not included).

We highly recommend that you install a servo inside the

float. It is easy to do and it makes installation/removal of the

floats on the aircraft easier.

Floats increase the weight of the model they are installed

on. In addition, water drag and surface tension increase the

amount of power required for takeoff. In-flight drag is also

greatly increased.

If your model had “adequate” power before floats are installed,

it will likely be very marginally powered with the floats. It is

recommended that you use an engine in the upper end of the

recommended power range with these floats.

For the .40 size Great Planes Piper J-3 Cub ARF, we recommend

an O.S.

®

.46 FX 2-stroke or an O.S. FS 70 4-stroke engine.

❏

1/2 oz. [15g] Thin Pro

™

CA (GPMR6001)

❏

1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❏

Pro 6-minute epoxy (GPMR6045)

❏

2-56 Tap and Drill (GPMR8100)

❏

Stick-on segmented lead weight (GPMQ4485)

❏

#1 Hobby knife (HCAR0105)

❏

#11 blades (5-pack, HCAR0211)

❏

Clear waterproof tape

❏

Drill bits: 1/16” [1.6mm], 5/64" [2mm], 1/8" [3.2mm].

(25/64" or 3/8" [9.9 or 9.5mm] for optional

servo installation.)

❏

Razor saw

❏

2 oz. [57g] spray CA activator (GPMR6035)

❏

CA applicator tips (HCAR3780)

❏

CA debonder (GPMR6039)

❏

Mixing sticks (50, GPMR8055)

❏

Mixing cups (GPMR8056)

❏

Pliers with wire cutter (HCAR0630)

❏

Denatured alcohol (for epoxy clean up)

❏

Z-bend pliers (HCAR2000)

❏

Rotary tool such as Dremel

®

❏

Rotary tool reinforced cut-off wheel

❏

Servo horn drill (HCAR0698)

❏

CG Machine

™

(GPMR2400)

For internal servo:

❏

(1) standard servo

❏

(1) 12" [300mm] servo extension

❏

(1) Y-harness

Hardware & Accessories

Optional Supplies & Tools

Adhesives & Building Supplies

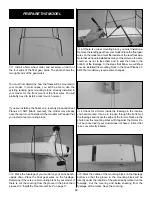

PREPARATIONS

POINTS TO CONSIDER

3