❏

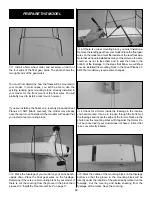

1. Use the servo tray to mark the outline of the tray on

one of the floats with a fine-tipped marking pen as shown in

the photo above. The tray should be located 1/2" [13mm] aft

of the rear groove in the float. This float is now the right float.

❏

2. Very carefully cut the marked area from the float with

a razor saw. The piece you cut out will be used as the tray

cover, so use care not to damage it. Mark the end of the

cover that was facing forward.

❏

3. Glue the servo tray to the inside of the cover with

epoxy. Use some medium grit sandpaper to rough up the

inside of the cover first. Mark the tray indicating which end

of the cover faces forward.

Note: The tray may not have the cutout shown in the

above photo.

❏

4. Clean any resin residue from the tray opening in the

float. Trim any resin from the hardwood mounting rail inside

the float. Put one of the 1/4" x 3/8" x 3-1/2" [6.4 x 9.5 x

89mm] basswood servo tray rails in the float, butting one

end against the mounting rail. Mark the rear of the opening

on the rail. Transfer the mark to the other rail as well.

❏

5. Glue a 1/8" x 3/8" x 1/2" [3.2 x 9.5 x 12.7mm] ply rail

spacer to each of the servo tray rails as shown in the photo.

In the photo, the mark is to the left of the spacers.

❏

6. Using medium CA, tack glue the servo tray rails into

the float opening with the spacers toward the rear of the

float. Scuff the area with some medium grit sandpaper to

improve the adhesion.

❏

7. Trial fit the servo tray to the top of the rails. If the tray

sticks up above the top of the float, remove the servo tray

Install the Steering Servo

ASSEMBLY

5