❏

3. Drill 1/16" holes in the mount plate. Then use #2 x

3/8" sheet metal screws to fasten a 1/8" hump strap and

outer pushrod tube with pushrod. Connect the swivel clevis

to the swivel on the rudder shaft.

❏

4. Mount an additional control horn (included with float

kit) on the right side of the rudder.

❏

5. Cut off one side of the

base from two 1/8" nylon hump

straps as shown in the sketch.

❏

6. Hold the outer pushrod tube and cable along the

bottom of the fuselage in a position that will provide a gentle

loop from the float to the rudder as shown in the photo.

Where the pushrod tube meets the fuselage, remove a

section of covering and install another die-cut plate.

❏

7. Fasten the guide tube to the aft strut with a nylon tie.

❏

8. Drill a 1/16" hole and secure the cable guide tube to

the mount plate with one of the cut-off hump straps and

#2 x 3/8" sheet metal screws.

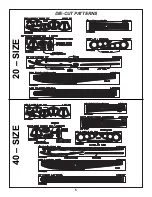

20 - 40 Floats only

After performing steps A and B, continue with step 8.

A. Screw a threaded coupler to a nylon clevis. Then

temporarily fasten the clevis and coupler to the rudder

horn. Holding both the water rudder on the float and the

rudder on the model in a neutral position, determine the

length of the pushrod cable, remove it from the guide tube,

then cut it to length. Hint: A Great Planes cut-off wheel

(GPMR8200) works great for cutting cable like this without

fraying the end. Cut the guide tube to a length so that it will

not interfere with the threaded coupler when it is soldered

onto the cable. There must be enough clearance to allow

the cable to slide freely.

Connect the Rudder

18

Summary of Contents for Sport Floats

Page 4: ...4 DIE CUT PATTERNS 60 SIZE...

Page 5: ...5 DIE CUT PATTERNS 20 SIZE 40 SIZE...

Page 21: ......