13.

INSTALL ALL CONTROL SURFACES AND

CONTROL HORNS

Flex the hinges back and forth a few times and

then glue the hinges into the rudder and fin slots; at the

same time glue the tiller arm of the tail wheel into the

rudder leading edge. Lightly sand both surfaces of the

hinges, put epoxy

into each hinge slot and

place the hinge in place. Use

2-56

screws and backplate

and attach the nylon horn to the rudder over the tail wheel

tiller arm positionfor extra support. Glue the elevator joiner

wire

to the elevators. Glue the hinges to the elevators and

stabilizer in the same manner as above. Attach the nylon

elevator horn and backplate to the bottom of the right

elevator with 2-56 screws. Glue the aileron torque arms

into the ailerons as you glue the hinges into the ailerons

and wing trailing edge.

14.

INSTALL THE CANOPY

Cut the canopy on the cut lines scribed in the

plastic. You can dye the canopy using Rit dye. Follow the

instructions on the box. Remove the canopy from the dye

when the desired tint is achieved. Glue the canopy to the

fuselage with cyanoacrylate glue. Seal the edge with strip-

ing tape.

15.

ASSEMBLE THE WHEEL PANTS

Cut and trim the wheel pant halves on their

parting lines that you find on the inside of the pants. You

can score this line with an X-Acto knife and break on the

line or simply cut on the line with a knife.

Sand the edges of the wheel pants smooth. An

easy way to

do this is to lay your sandpaper down on a

flat surface and move the pants over the sandpaper. This

way you are assured of a straight, flat edge when you

finish.

Cut a starter hole in one half of each pant in

the area of the wheel opening to make it easier to cut out

the opening later after the halves are glued together. Cut

the starter hole at the join line. Using cyanoacrylate (in-

stant glue), join the two halves together. Note that there

is a right and a left half to the wheel pant. Make sure you

have a good fit before you glue the two halves together.

When the halves are joined, sand lightly along the join

lineon the outside of the pant to get a smooth appearance.

Use your wheel and measure and mark the

area to be cut out of the pant for the wheel opening. Cut

out this area.

Find the tape locations on the insideof the pant

in Figure

1.

Use 60-100 coarse sandpaper and sand the

areas where you will put the tape.

Reinforce the inside of the wheel pants with

fiberglass tape. Cut the tape into one inch squares. You

should have eight pieces of tape when you finish cutting.

Use 5 minute epoxy and piece of tape at each of the

places you sanded before. Let the tape hang out of the

wheel opening. Cut the excess

off when the epoxy isdry.

23

TAPE

’

-AXLE

HO

L

E

Figure 1

16.

MOUNT THE WHEEL PANTS AND WHEELS

Mark the position of the axle hole on the innei

side of each wheel pant. Drill a clearance hole at this

location for your gear wire or axle bolt. See Figure

1.

Mark the positionof the brass plate on the gear

Do this by temporarily placing the wheel pant on the gear

Position the pant so it does not touch the ground and is

level or in the correct position for your model. Mark the

position of the brass plate on the gear and on the outside

of the pant. Remove the wheel pant! Solder the brass

plate to the gear using Sta-Brite silver solder. Position and

solder the other brass plate in the same manner.

Posiiton the

1 / 8

plywood plate on the inside

of the wheel pant opposite the brass plate on the gear,

Temporarily put the wheel pant back on the gear to find

this position. The ply plate is used as a backup plate for

the brass plate

so do a good job of lining these two plates

up. When you have the correct positions for the ply plates,

use 5 minute epoxy and glue them to the inside of the

wheel pants. Let the ply plates dry.

Drill the axle hole through the ply plates in the

pants.

Using the brass plate as a guide, drill two pilot

holes through the wheel pants and the ply back up plate

for the

#2

x

3/8”

screws.

Trial fit the wheel pant assembly to the gear by

attaching the screws provided, wheels and wheel collars

to hold the wheels to the gear. If all is in the correct position,

remove the assembly from the gear. See Figure

2.

LANDING GEAR

WHEEL PANT

WHEEL COLLARS

BRASS PLATE

WHEEL

Figure

2

Paint the wheel pants. First, sand lightly with

wet/dry

320-400

sandpaper but use it dry. Use K&B primer

or automotive primer. Sand the primer after it is dry. You

need only to sand the primer lightly. Put on the final coat

of paint. Spraying works the best for the final coat but

brushing the paint will give you good results also.

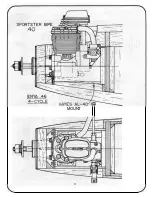

Summary of Contents for Sportster Bipe 40

Page 25: ...MOUNT...

Page 26: ...HAYES AL 60...

Page 31: ...I Use trim MonoKote and these letters to create your trim scheme on your Sportster...