❏

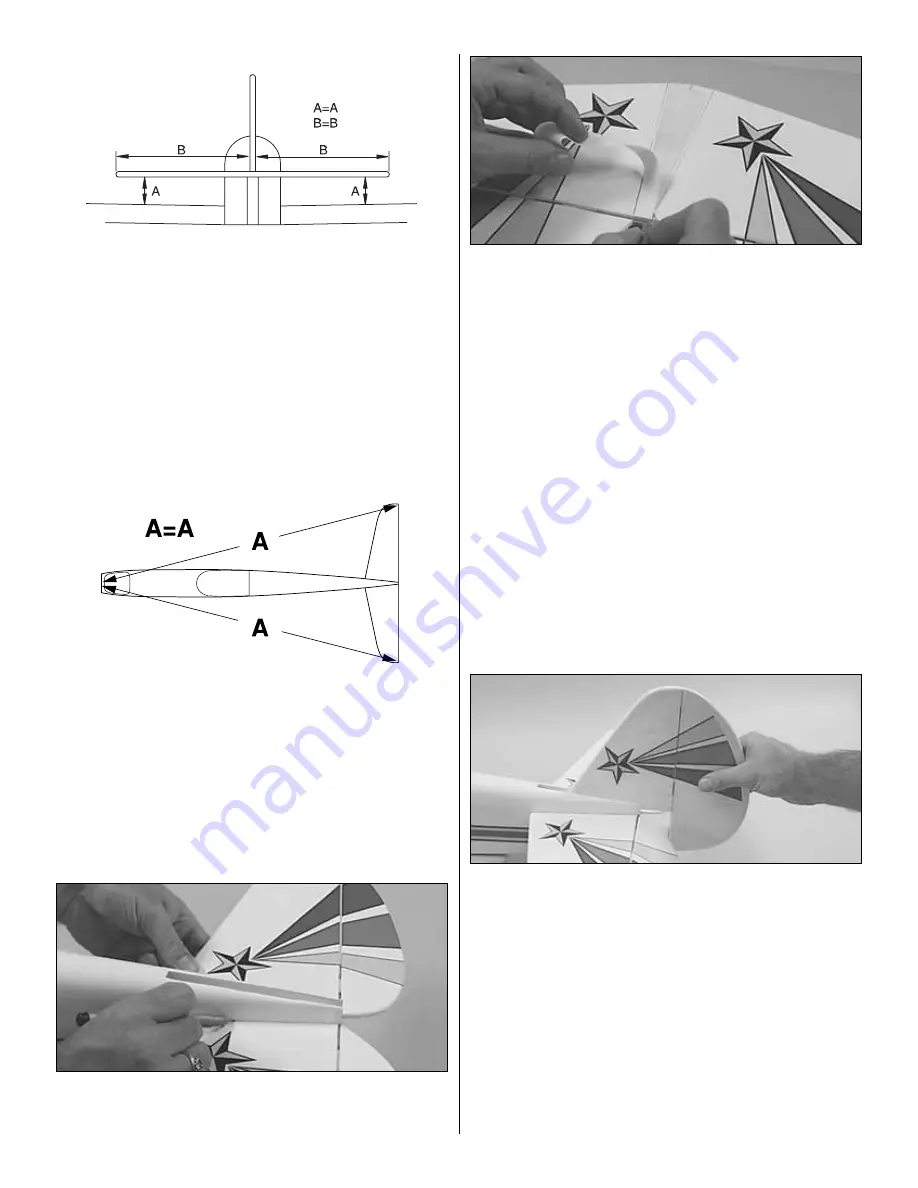

2. Insert the stabilizer into the horizontal stabilizer slot so

it is centered in the fuselage (A). Place the wing onto the

fuselage and secure it with the 1/4-20 x 2" nylon bolts. View

the plane from behind at a distance of about 8 feet [2.4m] to

check the alignment of the stabilizer to the wing (B). If the

stabilizer is not parallel to the wing, remove the stabilizer

and sand the stabilizer base

slightly

on the

high side.

Replace the stabilizer and check the alignment. Continue

this process until the wing and stabilizer are parallel.

❏

3. Attach a piece of string with a T-pin to the center of the

fuselage as shown. Hold the string to one corner of the

horizontal stabilizer. Mark the position on the line, and then

swing the line over to the opposite tip on the stabilizer. If the

mark does not line up, adjust the positioning of the stabilizer

and repeat the “mark and swing” procedure until the

stabilizer is in proper alignment.

❏

4. With the stabilizer properly aligned, use a felt-tip pen to

trace around the tail of the airplane on the top and bottom of

the horizontal stabilizer.

❏

5. Remove the stabilizer and draw two additional lines on

the top and two on the bottom, 1/16" [1.5mm]

inside

the

lines drawn in the previous step. Next, carefully cut through

the covering using a NEW #11 knife blade or soldering iron

at the inside lines and remove the covering from the center

on the top and bottom.

If you are using a hobby knife, do

not cut the wood under the covering! This will seriously

weaken the stabilizer and could easily cause the

stabilizer to break in flight.

If the stab breaks, the plane

has a very good chance of crashing. It is best to be

very

careful when making this cut not to cut into the wood. The

covering must be removed from the center of the stab, or the

bond between the fuselage and stabilizer will be insufficient

and the stab may simply come off in flight.

❏

6. Mix 1/4 oz. [7ml] of 30-minute epoxy. Using a mixing stick,

apply a good layer of epoxy in the stabilizer opening in the

fuselage. Place a thin layer of epoxy on the stabilizer in the

area where the covering was removed. Insert the stabilizer

into the slot from the rear and check the alignment. Wipe off

any epoxy that squeezes out using a paper towel and

rubbing alcohol. Recheck the alignment several times while

the epoxy cures. Allow the epoxy to fully cure before

continuing to the next step.

❏

7. Test fit the fin into the slot in the top of the fuselage. Slide

the fin forward until the leading edge of the rudder is against

the fuselage. Align the hinge on the bottom of the rudder

with the slot in the aft edge of the fuselage. Check the

alignment of the fin with the centerline of the fuselage. A

straightedge against one side of the fin can be used to

check alignment. Make adjustments to the slot if necessary.

❏

8. With the fin properly aligned, use a felt-tip pen to trace

a line along both sides of the bottom of the fin as was done

with the stabilizer. Remove the fin and draw an additional

line 1/16" [1.5mm]

below

the lines drawn in the previous

step. Next, carefully cut through the covering using a new

#11 knife blade or soldering iron at the inside lines and

remove the covering from the center on the top and bottom.

9