13

❏

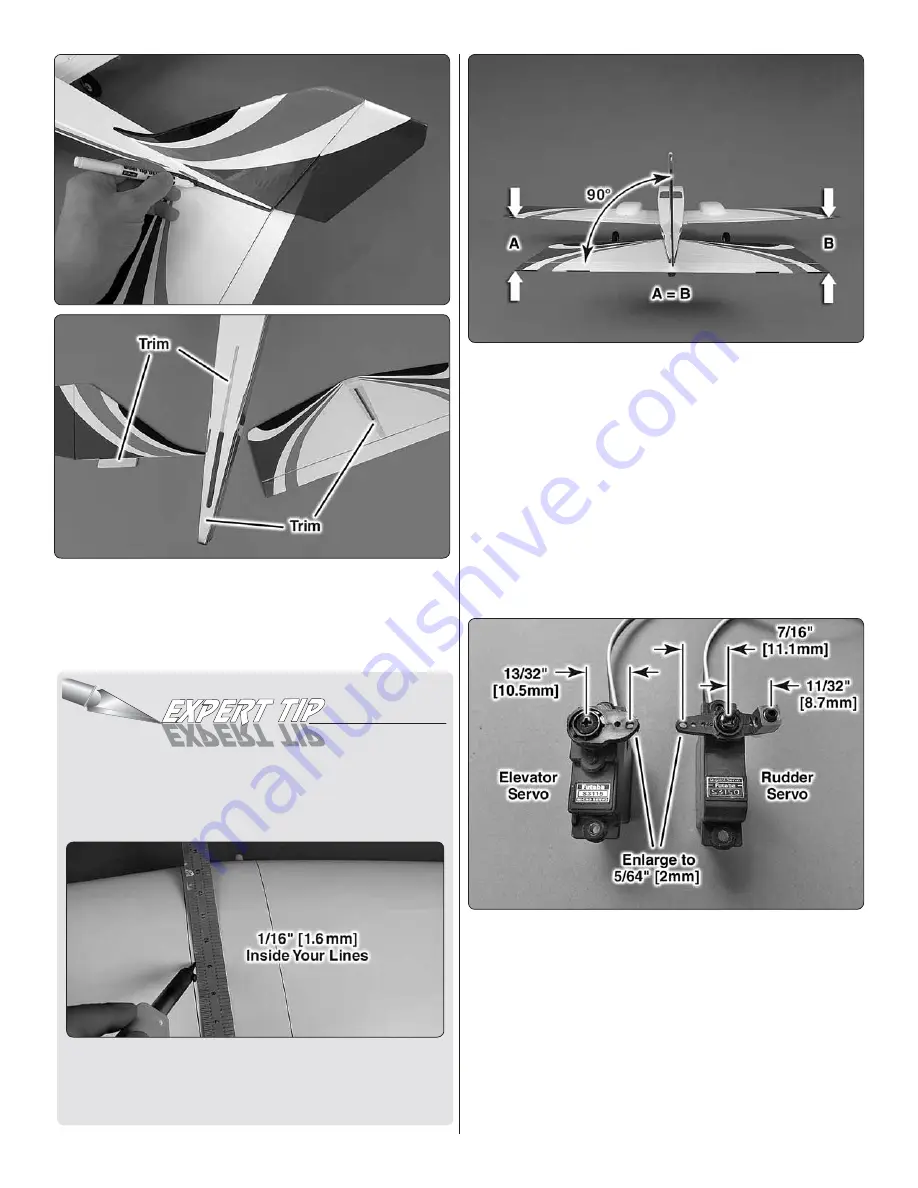

4. Fit the vertical fi n and horizontal stabilizer into place.

Use a felt tip marker to trace around the fuselage onto the tail

parts top and bottom and left and right side. Trace around the

fi n onto the fuse. Remove the tail parts and trim the covering

away 1/16" [1.6mm] inside your lines as shown.

HOW TO CUT COVERING FROM BALSA

Use a soldering iron to cut the covering from the stab. The

tip of the soldering iron doesn’t have to be sharp, but a

fi ne tip does work best. Allow the iron to heat fully.

Use a straightedge to guide the soldering iron at a rate

that will just melt the covering and not burn into the wood.

The hotter the soldering iron, the faster it must travel to

melt a fi ne cut. Peel off the covering.

❏

5. Re-insert the horizontal stabilizer and vertical fi n into

the fuse. With the wing in place, stand behind the model

approximately 10 feet [3m] and confi rm that the stab sits

parallel with the wing. If not, weight can be added to the high

side while gluing the stab in place, or the stab pocket can

be lightly sanded until the stab and wing sit parallel. When

satisfi ed, remove the stab and fi n and coat the exposed

wood with 30-minute epoxy (although messy, a more reliable

glue joint can be attained if you also coat the inside edges of

the stab pocket). Reinstall the stab and fi n. Wipe away any

excess epoxy with denatured alcohol and let the epoxy cure

undisturbed. When cured, the wing can be removed from

the fuselage and set aside as it will not be needed until the

fi nal set up of the plane.

Install servo arms onto the elevator and rudder servos as

shown. A brass screw lock connector is needed for the

nose gear pushrod. Enlarge the holes for the rudder and

elavator pushrods using a 5/64" [2 mm] drill bit. We chose

a high torque servo for the rudder for more responsive yaw

control in fl ight.