❏

5. Test fit the ailerons to the wing with the hinges. Use a

fine-point ballpoint pen to mark the wing and ailerons at the

middle of each hinge.

❏

6. Separate the ailerons from the wing and take out all

the hinges.

❏

7. Drill a 3/32" [2.4mm] hole, 1/2" [13mm] deep at the

marks you made in the center of each hinge slot. This space

will allow the CA to “wick” in. Follow with a #11 blade to clean

out the slots. Hint: If available, use a high-speed rotary tool

to drill the holes.

❏

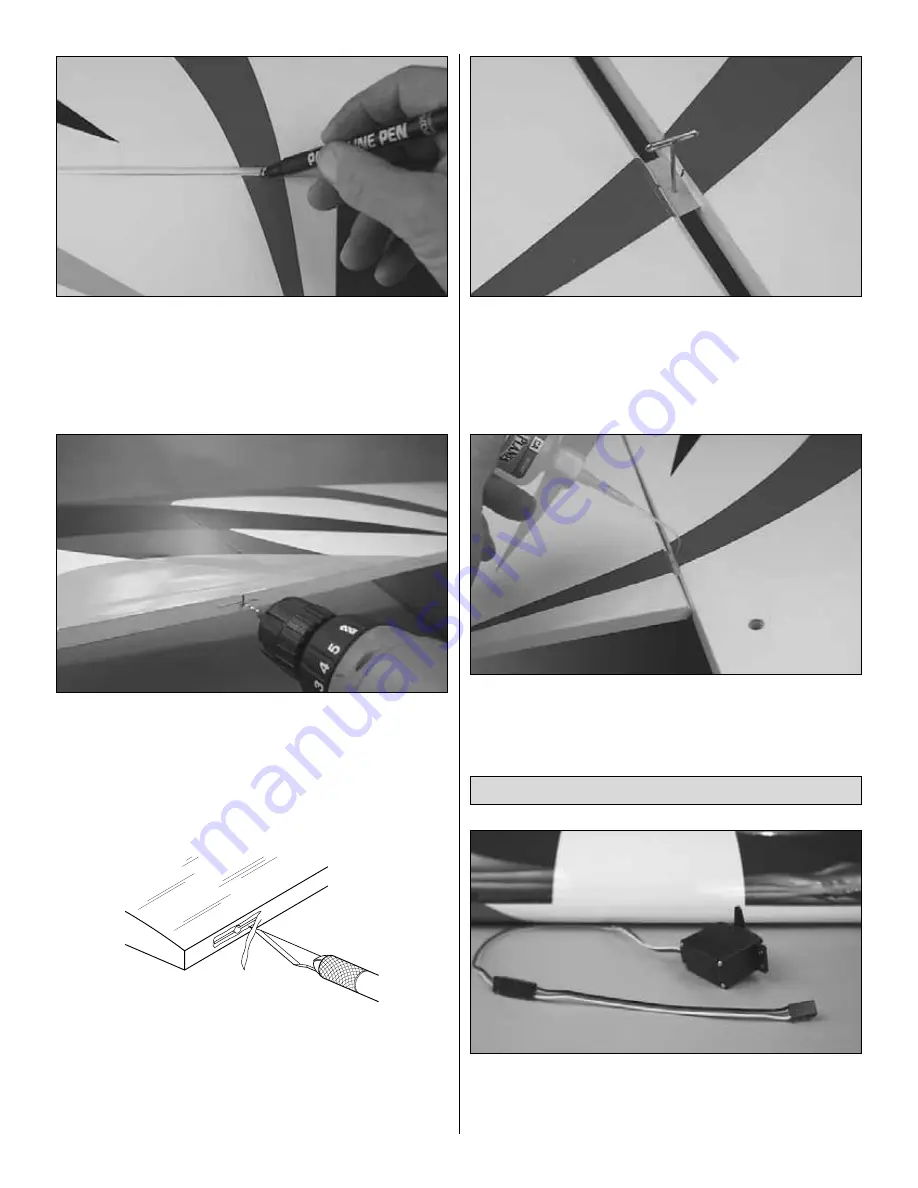

8. Cut a small strip of covering from both sides of each

hinge slot. If this is not done the covering may interfere with

the penetration of the CA into the slot and may also interfere

with the free movement of the aileron.

❏

9. Stick a pin through the center of each hinge. Fit the

ailerons to the wing with the hinges. The pin will keep the

hinge centered. Remove the pins from the hinges. Adjust the

ailerons so there is a small gap–just enough to see light

through or to slip a piece of paper through–between the

aileron and the wing.

❏

10. Apply six drops of thin CA to the top and bottom of

each hinge. Do not use CA accelerator. After the CA has

fully hardened, test the hinges by pulling on the ailerons.

❏

1. Add servo extensions to the two aileron servos, so that

the total length of the leads will be at least 12" [305mm] from

the servo to the end of the extension. Using tape or heat shrink

tubing, securely attach the servo extension to the servo.

Install the Aileron Servos and Pushrods

AWAY FROM THE SLOT

CUT THE COVERING

8