2

INTRODUCTION

The U-Can-Do SF has the impressive fl ight characteristics

of the original version with a refi ned design to speed up

assembly, a fresh appearance with a new trim scheme, and

now the provisions for a brushless setup. Like all of the latest

Great Planes ARFs, many of the tasks typically required to

be done during assembly have already been completed for

you at the factory including pre-hinged ailerons and rudder,

pre-glued canopy, and trimmed covering.

For the latest technical updates or manual corrections to

the Great Planes U-Can-Do SF ARF visit the Great Planes

web site at www.greatplanes.com. Open the “Airplanes” link,

then select the U-Can-Do SF ARF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

Academy of Model Aeronautics

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club. The AMA is the governing body of model

aviation and membership is required to fl y at AMA clubs.

Though joining the AMA provides many benefi ts, one of the

primary reasons to join is liability protection. Coverage is not

limited to fl ying at contests or on the club fi eld. It even applies

to fl ying at public demonstrations and air shows. Failure to

comply with the Safety Code (excerpts printed in the back of

the manual) may endanger insurance coverage. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. There are over

2,500 AMA chartered clubs across the country. Contact the

AMA at the address or toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your U-Can-Do SF ARF should not be considered a toy,

but rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the U-Can-Do SF, if not assembled and operated

correctly, could possibly cause injury to yourself or spectators

and damage to property.

TABLE OF CONTENTS

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Academy of Model Aeronautics . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . 2

DECISIONS YOU MUST MAKE

. . . . . . . . . . . . . . . . . . . . . 3

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Glow Engine Recommendations . . . . . . . . . . . . . . . . . 3

Brushless Motor Recommendations . . . . . . . . . . . . . . 4

ADDITIONAL ITEMS REQUIRED

. . . . . . . . . . . . . . . . . . . 4

Required Hardware & Accessories . . . . . . . . . . . . . . . 4

Adhesives and Building Supplies . . . . . . . . . . . . . . . . . 4

Optional Supplies and Tools. . . . . . . . . . . . . . . . . . . . . 4

Building Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IMPORTANT BUILDING NOTES

. . . . . . . . . . . . . . . . . . . . 5

KIT INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ORDERING REPLACEMENT PARTS

. . . . . . . . . . . . . . . . 5

KIT CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PREPARATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

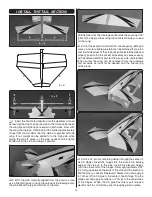

INSTALL THE AILERON SERVOS,

PUSHRODS AND BELLY PAN

. . . . . . . . . . . . . . . . . . . 6

INSTALL THE TAIL SECTION

. . . . . . . . . . . . . . . . . . . . . 10

INSTALL THE MAIN LANDING GEAR

. . . . . . . . . . . . . . 12

INSTALL THE POWER SYSTEM

. . . . . . . . . . . . . . . . . . . 13

Brushless Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Glow Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INSTALL THE RECEIVER,

BATTERY, AND SWITCH

. . . 20

FINISH THE MODEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Optional Side Force Generators . . . . . . . . . . . . . . . . 24

Apply the Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

GET THE MODEL READY TO FLY

. . . . . . . . . . . . . . . . . 24

Check the Control Directions . . . . . . . . . . . . . . . . . . . 24

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . . 25

Proper Pushrod Hookup; Avoiding Flutter,

Maximizing Servo Output Torque . . . . . . . . . . . . . 26

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . 27

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . . 27

PREFLIGHT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . 27

Balance Propellers . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ground Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ENGINE SAFETY PRECAUTIONS

. . . . . . . . . . . . . . . . . 28

AMA SAFETY CODE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Radio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

CHECK LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

FLYING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fuel Mixture Adjustments . . . . . . . . . . . . . . . . . . . . . 29

Takeoff

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3D Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30