20

❏

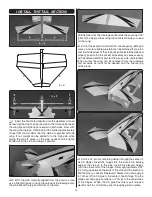

17. Bend the throttle pushrod so that it can reach the

throttle arm on the carburetor without contacting any part of

the engine or mount. Thread a nylon clevis onto the pushrod

and slide a silicone clevis retainer onto the clevis. Insert the

pushrod into the outer pushrod tube and connect the clevis

to the outer hole in the throttle arm.

❏

18. Cut all but one of the arms from a servo arm. Install a

screw-lock pushrod connector into the hole in the remaining

arm that is approximately 27/64" [10.5mm] from the center

of the servo arm. Secure the screw-lock connector with a

screw-lock connector retainer. Loosely thread a 4-40 set

screw into the screw-lock connector.

❏

19. Center the throttle servo using your radio system

(50% throttle). Insert the aft end of the throttle pushrod into

the screw-lock connector and attach the servo arm to the

throttle servo perpendicular to the servo case (be sure to

install the servo arm screw). Adjust the carb barrel so that it

is close to 50% open and tighten the set screw in the screw-

lock connector. Test the operation of the throttle using your

transmitter and confi rm that the carb barrel properly opens and

closes. Make any adjustments to the pushrod as necessary.

When satisfi ed, cut off the excess pushrod 1/4" [6.4mm] aft

of the screw-lock connector.

INSTALL THE RECEIVER,

BATTERY, AND SWITCH

❏

1. Wrap your receiver battery in 1/4" [6.4mm] foam rubber

(not included) to protect it from motor vibration. If you have

powered your model with a brushless motor, then a standard

AA 4.8V fl at receiver pack will fi t at the aft end of the battery

tray. If you installed a glow engine, a LiFe battery (lithium

iron phosphate LiFePO4) can also be used because there

is more space on the tray available behind the fuel tank. Cut

pieces from the hook and loop material to make straps to

secure the battery to the tray.