8

the control horns over the hardwood blocks in the ailerons

(if you cannot see them, hold the aileron at a shallow angle

in good lighting or use a small pin to puncture the covering).

When satisfi ed, use a felt-tip pen to mark the location of the

control horn mounting holes onto the aileron. Repeat this

step for the other aileron.

❏

7. Drill 5/64" [2mm] holes at the marks you made. Thread

a #4 x 5/8" [16mm] self-tapping screw into each hole and

back it out. Apply a drop of thin CA to each hole to harden the

surrounding wood. Install the control horns onto the ailerons

using eight #4 x 5/8" [16mm] screws.

❏

8. With the ailerons in the neutral position (use tape or

small clamps to hold them in place), mark the pushrod wires

where they cross the outer holes in the servo arms.

❏

9. Clean the area of the pushrods between the marks

you made and the threads with a paper towel dampened

with denatured alcohol. Apply a thin coating of epoxy onto

the pushrods from the end of the threads to approximately

3/4" [19mm] from your marks. Slide the two 4-1/8" [105mm]

carbon tubes over the pushrods up to the pushrod threads.

Wipe away any excess epoxy with denatured alcohol and

allow the epoxy to cure undisturbed.

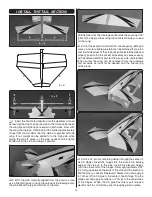

Servo Horn

1/16" [1.6 mm]

Pushrod Wire

FasLink

❏

10. Make a 90 degree bend at the mark on each pushrod

and cut off the excess pushrod 1/4" [6mm] ends beyond the

bends. Attach the pushrods to the servo arms using nylon

FasLinks. Thread the clevises up or down on the pushrods

as necessary to center the ailerons with the servo arms still

perpendicular to the servo cases. When satisfi ed, slide silicone

clevis retainers onto the ends of the clevises to secure them.