D D 1. Trim one end of the 1-1/4" x 24" balsa aileron to

the same angle as the center TE.

D D 2. With a gap of 1/16" between the aileron and the

center TE, Mark the end of the aileron approximately 1/16"

past the wing tip. This will allow you to sand the aileron

flush with the wing tip later. Cut the aileron at the mark.

D D 3. Draw a centerline on the LE of the aileron.

D 1. Cut the "spreader bar" from the supplied Great Planes

engine mount. Use a hobby knife to remove any flashing so

the halves fit together properly.

D 2. Temporarily mount the engine mount to the firewall

with four 6-32 x 1" machine screws and #6 washers. Do not

tighten the screws all the way so you can adjust the mount.

D 3. Place your engine on the mount and slide the halves

in or out so the engine fits. When the engine mount is

adjusted and centered, tighten the mounting screws.

D D 4. Cut out four aileron hinges from the leftover

hinge material.

D D 5. Mark the location for the hinges on the aileron and

wing. Cut the hinge slots and without using glue, test fit the

aileron to the wing.

D D 6. Remove the aileron from the wing. Mark the "bevel

to" lines and trim the LE of the aileron to a "V" as shown on

the plan.

D 7. Perform steps 1 through 6 to fit the remaining aileron

onto the wing.

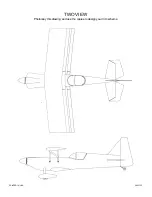

Now that the fuselage and wings are assembled, remove

the cabane from the fuse and rough sand the completed

airplane. Refer to the cross-section drawings often while

sanding. At this point we just want to blend the fuse sides

with the turtledeck and front deck and sand a radius at the

joint between the bottom and sides of the fuse.

D 4. Position the engine on the mount so that the drive

washer (or the backplate of the spinner) is 4-15/16" away

from the firewall. Refer to the Expert Tip that follows, then

mark and drill the engine mounting holes for the #6 x 3/4"

engine mounting screws.

HOW TO ACCURATELY MARK & DRILL THE ENGINE

MOUNTING HOLES ON THE ENGINE MOUNT

A. Use C-clamps to hold the engine in position.

B. Use a torch or a lighter to heat the end of a sharpened

wire rod and mark the center of the engine mounting

holes. It just takes a little pressure of the heated rod to

dimple the plastic.

33