D D 19. Slide a silicone retainer on the pushrod. Use a

5/64" or #48 drill bit to enlarge the hole in the control horn

on the bottom aileron only. Insert the "Z-bend" in the

control horn and attach the clevis to the control horn on the

aileron of the top wing. Slide the retainer over the clevis to

secure it to the control horn.

D 20. Assemble the other aileron pushrod following the

same procedure.

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

ELEVATOR MOVES UP

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

CARBURETOR WIDE OPEN

The throws are measured at the widest part of the

elevators, rudder and ailerons. Adjust the position of the

pushrods at the servo horns to control the amount of throw.

You may also use the ATV'S if your transmitter has them but

the mechanical linkages should still be set so the ATV'S are

near 100% for the best servo resolution (smoothest, most

proportional movement).

Note: We found that some mixing of the elevator and

aileron with the rudder will make flying knife-edges easier.

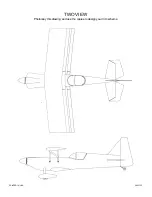

D 1. Mount both wings on the fuselage and block-up the

tail so that the stab is level.

D 2. Set an incidence meter on the bottom wing. Take

measurements next to the fuse and at the wing tips. The

incidence on the bottom wing should be 0°.

D 3. Check the incidence of the top wing. It should be 0°. If

the incidence needs to be changed, #6 washers can be

inserted under the 6-32 nuts on top of the cabane.

D 4. After the incidence is set, cut off the 6-32 bolts above

the locking nuts that hold the top wing in position.

We recommend the following control surface throws:

Elevator

Rudder

Ailerons

Mixing

High rate

5/8"

1-1/4"

1/4"

Rudder/Elevator

Low rate

7/16"

1-1/4"

3/16"

left rudder -1/8" up elevator

right rudder -1/16" down elevator

Rudder/Aileron

left rudder -1/16" right aileron

right rudder -1/32" left aileron

Note: If your radio does not have dual rates, set the

control surfaces to move between the high rate and

low rate throws.

43