Glue the Fairing onto the Wing

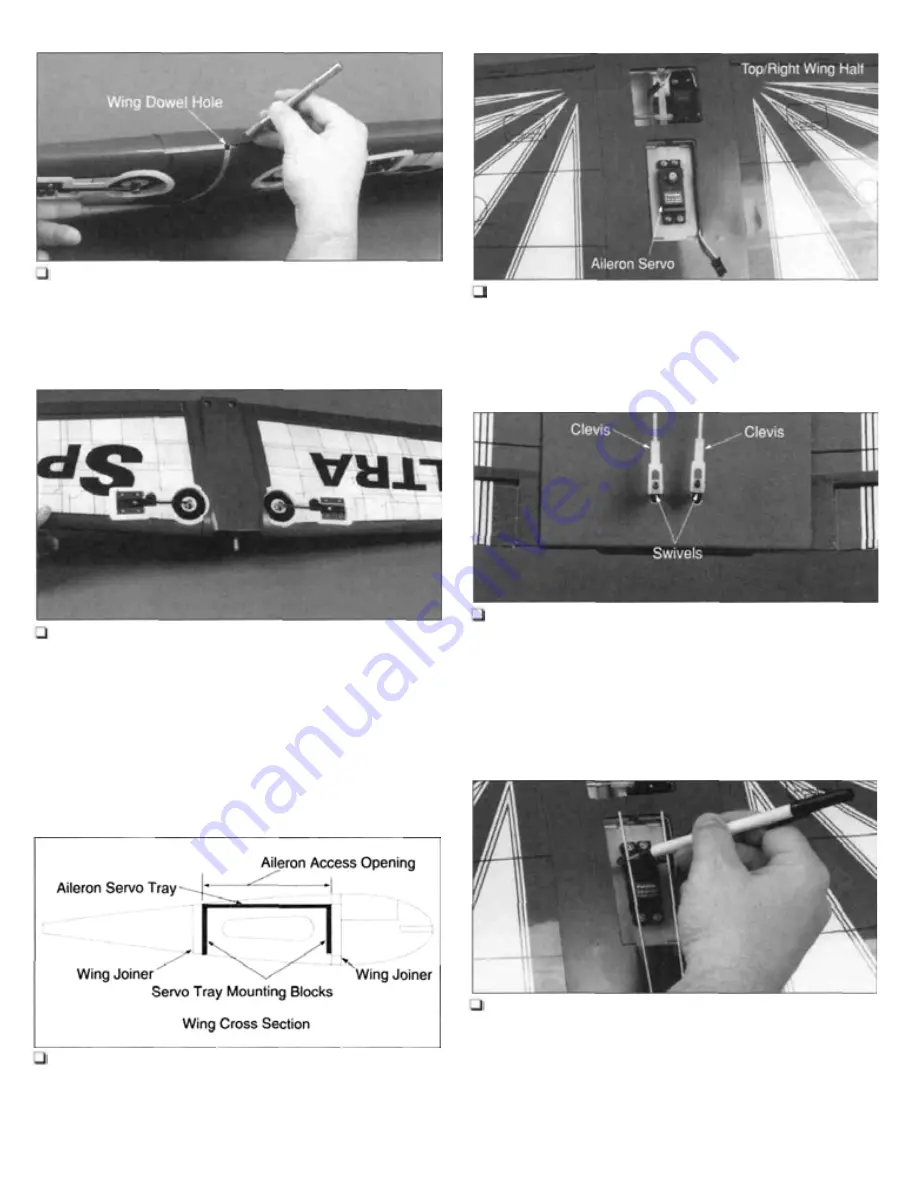

Mount the Aileron Servo

12. Use thick CA+ to glue the top fairing to the top of

the wing. Remove the plastic that is covering the wing

dowel hole on the leading edge of the wing. Proceed to

glue the bottom fairing to the bottom side of the wing and

remove the remaining plastic covering the dowel hole.

Insert the Wing Dowel

2. Mount the aileron servo in the servo tray using the

screws, grommets and rubber mounts supplied with servo.

Place the control horn on the aileron servo in the neutral

position.

Connect the Clevises

3. Locate the nylon swivels and thread them onto the

13. Use 6-minute epoxy to glue the hardwood wing

dowel into the leading edge of the wing. Work epoxy into

the dowel hole using a sliver of wood. Apply epoxy to the

dowel and insert the dowel. Leave 1/2" of dowel protruding

from the wing. Apply the foam rubber seal to the front edge

of the wing fairing (see Step 11, page 10). Clean the

excess epoxy from the dowel using a paper towel and

rubbing alcohol.

Aileron Assembly

1. Trial fit the servo into the servo tray. Locate the

plywood servo tray mounting blocks and glue them into the

aileron servo tray opening using 6-minute epoxy. The tray

should be flush with the top of the wing joiners installed

earlier in Step 6, Page 7.

aileron torque rods until approximately 1/8" of threaded rod

is showing above the swivel. Thread the clevises onto the

control rods 15 full turns. Using the grooves on one side of

the clevis as a guide, snap the clevis onto the swivel. (It

may be necessary to use pliers to hold the control rod

while threading on the clevises.)

Connect the Pushrods to the Servo

4. Mark the control rod at the point that it crosses the

control horn holes, 1/2" from the center of the servo control

horn. Cut the control rod 1/4" past the mark and make a

L-bend at that mark. Center the servo and insert the

L-bend through the servo horn. Place a Nylon Faslink

Pushrod Connector on the L-bend and servo horn to

secure the pushrod. It may be necessary to enlarge the

holes in the servo horn using a 5/64" drill bit.

12