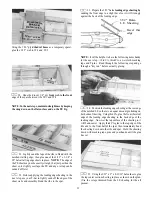

Method 2: Cut threads into the holes you just drilled

using a 6-32 tap and tap wrench. If you use this method you'll

have to supply your own bolts (6-32 x 1" socket head cap

screws) for attaching the engine to the mount. NOTE; 8-32

hardware is recommended if you are installing a 4-cycle

engine.

INSTALL SERVOS AND PUSHROD GUIDE

TUBES

NOTE: Although you may choose to wait until later, this is

the best time to install the pushrod guides, because the

fuselage is wide open and it is very easy to work inside.

IMPORTANT: Before proceeding, plan your servo and

pushrod installation. Especially note which side of the

fuselage the throttle pushrod and nose gear pushrod (if any)

will be located. Remember that the throttle arms of 2-cycle

and some 4-cycle engines are on opposite sides. It will be

helpful to actually sketch your pushrod locations on the plans

with a pencil. It is desireable for the throttle pushrod (and the

nosegear steering pushrod) to run along the sides of the

fuselage. It is also desireable (but not essential) for the rudder

and elevator pushrods to cross inside the fuselage, to avoid

any sharp bends.

1. Set the fuselage upside down on blocks at least

the brass tube method gives a much neater cut). Determine

the location of these holes from the plans. You may chuck

this brass tube in an electric drill to aid in getting through

F-6.

5. Insert the plastic pushrod tubes through the holes

you just cut and through formers F-6, F-5 and F-4.

1-inch high.

2. Trim the 3/16" x 1/2" x 3-5/8" ply servo rails to fit

between the fuse side doublers in the locations shown on the

plan. Temporarily mount your servos to the rails, then glue

the rails to the fuse side doublers. Lock the rails in place by

gluing scraps of plywood on the top and bottom of the rails.

3. Sand the outer surface of the pushrod guide tubes

with 100-grit sandpaper to provide a surface to which the glue

will adhere.

radio installation plan. Temporarily insert the 34"

pushrod wires into the tubes and hold them in the

correct position at the servo end. Keep the tubes as

straight as possible. Glue the tubes to the fuse sides

at the rear exit points using thin CA glue. Use scraps

of 1/8" balsa to anchor the tubes to F-5. Do not anchor

the tubes to F-4 at this time, to allow for slight

adjustment of their positions later.

7. Cut off the tubes at the exit points and sand them

flush with the fuse sides using a sanding block.

8. Temporarily install the engine mount, nosegear

(and nosegear steering arm if you are building a tricycle

configuration).

9. Cut 1/4" off the end of the steering arm, then drill

a 3/16" hole in F-l, just above the outer hole of the arm.

NOTE: The drill should be aimed toward the rudder servo to

avoid tight bends in the pushrod. The photo for this step is at

the top of the next page.

5/32" Collar

6. Route the pushrod tubes according to your

4. Use an Xacto knife to sharpen one end of a piece of

3/16" (outside diameter) brass tubing, then use this tubing to

cut the pushrod exit holes (you may use a 3/16" drill bit, but

Steering Arm

Cut off end

22

6-32 x 1/4" Screw