DECISIONS YOU MUST MAKE NOW

ENGINE AND MOUNT SELECTION

The recommended engine size range is as follows:

.60 - .65 cubic inch displacement 2-cycle

.70 - .91 cubic inch displacement 4-cycle

The engine you select will determine how you build the

fuselage, so it is important that you have the engine close at

hand while building.

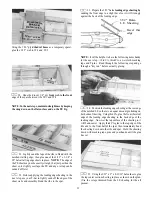

This kit includes the new Great Planes Adjustable

Engine mount. This mount will work on most .40-.60

2-Cycles and .40-.70 4-cycles. Cut or break the

"spreader bar" off each mount half. The surfaces

where the spreader bars were attached need to be

very smooth to allow the mount halves to fit together.

Snap the two mount halves together. Slide the mount

halves apart until the engine mounting lugs will sit

flat on the beams.

NOTE: If you choose to power your Ultra Sport 60 with a 4.

cycle engine, keep in mind that the RPM of your engine will

be considerably less than that of a 2-cycle engine; therefore,

you should select a higher pitch propeller to keep the speed

and overall performance roughly equivalent to that of a 2-

cycle engine. For example, an 11x7 or 11x8 prop would be

used with a .61 (2-cycle) engine; but an 11x11 prop may be

the best choice for a .91 4-cycle engine.

LANDING GEAR CONFIGURATION

The Ultra Sport 60 may be built with a "taildragger"

or "tricycle" landing gear configuration, and a retractable

main gear may be installed if you want to really ' 'clean up"

this airplane for ultra-smooth and precise aerobatics.

There is not. however, room for a nose gear retract;

therefore, if you want retracts, you'll have to use the "tail-

dragger" configuration.

OTHER ITEMS REQUIRED

• Four-channel radio with 4 servos (additional channel and

retract servo required if retracts are being used).

• Propellers (see engine instructions and above engine

notes for recommended sizes).

• Spinner (2-3/4" diameter)

• Fuel Tank (11 to 14 ounce)

• Main Wheels* - 2 (2-1/2" dia. for fixed gear and retract)

• Nose Wheel* - 1 (2-1/2" diameter, required for trike

only)

• Tail Wheel - 1 (1" diameter, required for taildragger

only)

• 5/32" Wheel Collars - 4 or 6

• 3/32" Wheel Collars - 2 (required for taildragger only)

• Iron-on Covering Material

• Silicone Fuel Tubing

• Wing Sealing Tape (or silicone sealer ... see instruc-

tions)

• Latex Foam Rubber Padding (1/4" thick)

• Dubro "E-Z Connectors" (or equivalent) - 2

• Main Gear Retracts: (optional)

Mechanical: Dave Brown 2-Gear Main, or

equivalent

Pneumatic: Robart #605 90-degree mains, or

equivalent (requires #188 air control kit)

• Plastic Pilot (Williams Bros. 2-5/8" scale)

•"Lightweight wheels are recommended.

SUPPLIES AND TOOLS NEEDED

2 oz. Thin CA Adhesive

2 oz. Medium or Thick CA Adhesive

2.5 oz. 30-Minute Epoxy

Hand or Electric Drill

Drill Bits: 1/16". 5/64", 3/32", 7/64", 1/8", 9/64". 5/32",

13/64", 7/32". and 1/4"

Sealing Iron

Heat Gun

Hobby Saw (Xacto Razor Saw)

Xacto Knife, #11 Blades

Pliers

Screw Drivers

T-Pins

Straightedge

Masking Tape

Sandpaper (coarse, medium, fine grit)*

T-Bar Sanding Block, or similar

Waxed Paper

Lightweight Balsa Filler

1/4-20 Tap, Tap Wrench

Vaseline Petroleum Jelly

Isopropyi Rubbing Alcohol (70%)

3M "77" Spray Adhesive (optional)

Dremel Moto Tool or similar (optional)

*NOTE: On our workbench, we have four 11" T-Bar

sanders, equipped with #50, #80, #100 and #150-grit sandpa-

per. This setup is all that is required for almost any sanding

task. We also keep some #320-grit wet-or-dry sandpaper

handy for finish sanding before covering.

4