18

❏

11. Fit two 3/16" [4.8mm] wheel collars onto the elevator

pushrod wires. Use a drop of thread locking compound on

the screw threads and fit two 6-32 x 1/4" SHCS. With both

elevators centered, tighten the collar locking screws to hold

the two wires together securely.

❏

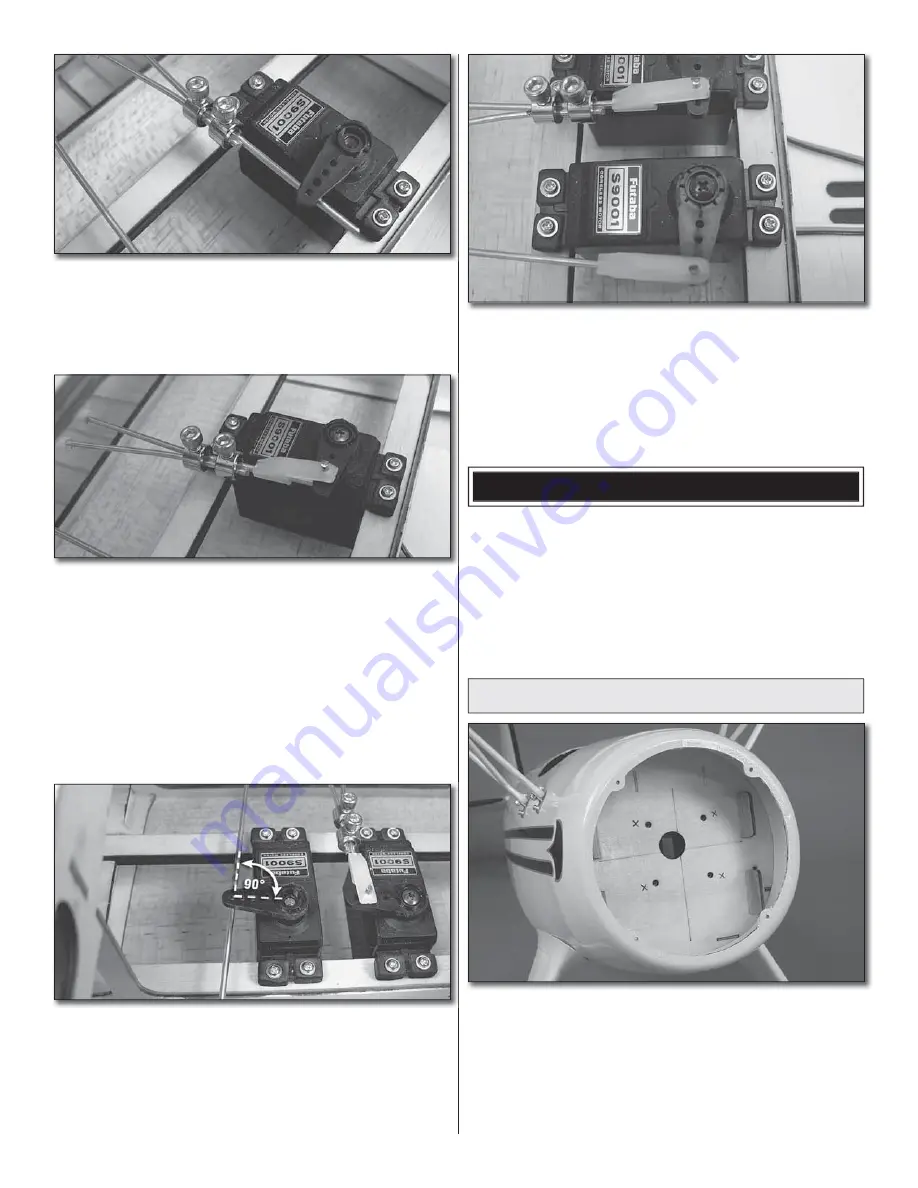

12. Mark the pushrod at the servo arm and make a 90°

vertical bend. Drill the second outermost servo arm hole

using a 5/64" [2mm] drill. Fit the pushrod to the servo arm.

Secure the pushrod with a nylon Faslink. Cut off the excess

pushrod wire. Install the servo arm screw.

❏

13. If you need to make any minor adjustments to the

elevators, make the adjustments at the individual elevator

clevises rather than at the collars. Remember to secure

the clevises with the silicone retainers when you are done

making adjustments.

❏

14. Use a 1/16" [1.6mm] drill bit to install the rudder servo

so that the outermost hole in the servo arm is aligned with the

rudder pushrod wire as shown.

Note:

The servo arm must

be positioned on the output shaft so that there is a 90° bend

between the arm centerline and the pushrod. Choose the

servo arm that aligns best and clip off the remaining servo

arms. Remember to harden the screw holes with thin CA.

❏

15. Mark the rudder pushrod at the servo arm hole and

make a 90° bend. Drill a 5/64" [2mm] hole. Install the pushrod

on the servo arm and secure it with a nylon Faslink. Cut off

the excess pushrod wire. Install the servo arm screw.

❏

16. Make any adjustments to the pushrod length to center

the rudder and re-secure the clevis with the silicone retainer.

GLOW ENGINE INSTALLATION

This section will cover the installation of an O.S. FS-1.20S-E

Surpass four-stroke glow engine. A two-stroke .91 sized

engine can be installed with a Pitts-style muffler. If you

are installing a different engine, please respect the firewall

to prop washer dimension of 6-11/16" [170mm]. Plywood

spacers are included that work with the two bolt patterns

etched on the firewall. This engine is best mounted with the

cylinder on the right side and the exhaust facing down.

Mount the Engine

❏

1. To install the O.S. FS-1.20S-E Surpass four-stroke

glow engine (or any engine using the supplied nylon engine

mount), drill the firewall at the four engraved “+” marks on the

firewall using a 3/16" [4.8mm] drill. These marks line up with

the two nylon engine mount halves that are supplied in this

kit. If you plan on using a different engine mount, please use

the vertical and horizontal centerline “crosshair” marks on

the firewall to line up the template that came with your mount.

Summary of Contents for Waco YMF-5

Page 40: ......