20

o

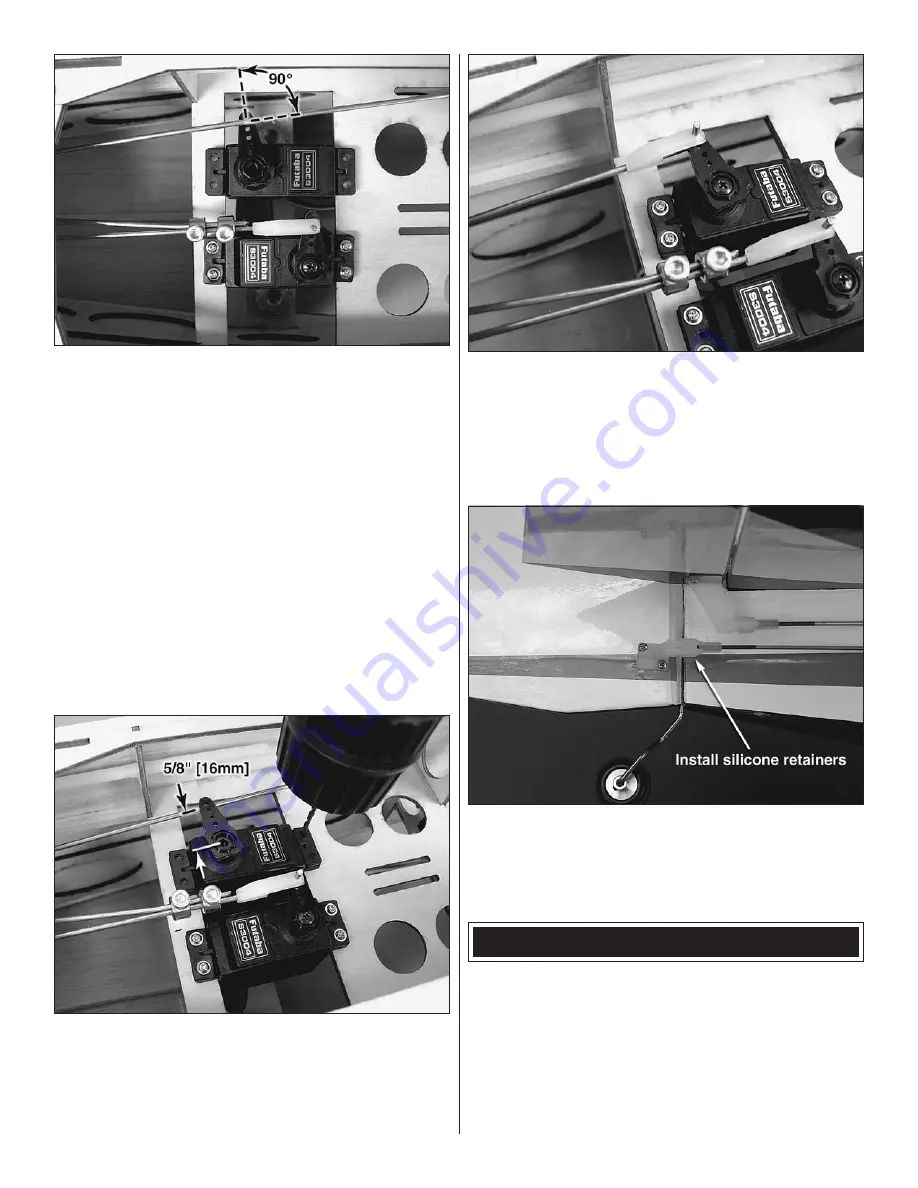

17 . Locate your rudder servo and servo arm that you set

aside earlier . If you didn’t do so already, center the servo

and remove the arm . Set the servo in the servo bay with the

output shaft facing aft as shown . Fit the servo arm so that

you choose the arm that is 90° to the

pushrod . Use a #48

drill bit to drill the outermost hole of the servo arm . Cut off the

unused servo arms .

o

18 . Hold the servo in position so that the rudder pushrod

is directly in line with the outermost hole of the servo arm

or about 5/8" [16mm] from the center of the servo output

shaft . Drill four mounting holes using a 1/16" [1 .6mm] drill bit .

Install the servo using the screws provided with your servo .

Remove the servo and harden the holes with thin CA .

o

19 . Set the rudder at neutral . Mark the rudder pushrod

at the servo arm and bend the rod straight up 90° . Attach

the pushrod to the servo arm using a nylon FasLink . Secure

the servo arm using the attachment screw provided with

your servo .

o

20 . With your rudder servo still centered, adjust the

rudder clevis so that the rudder is at neutral throw . When

you’re satisfied, slide the silicone retainers into position over

the clevises for the rudder, elevator, ailerons, and throttle .

GLOW ENGINE INSTALLATION

This section describes how to install an O .S . FL-70 four-

stroke glow engine . Two and four-stroke engine installations

are similar with the exception of throttle pushrod location .

If you choose to use a two-stroke engine, we recommend

using either the O .S . .46 AX or the O .S . .55 AX . When

installing an engine other than the ones recommended,

choose the throttle pushrod hole in the firewall that best suits

your application .

Summary of Contents for Z-526 ZLIN krobat

Page 40: ......