GMV5 HR Heat Recovery Cooling and Heating Mode Exchanger

2

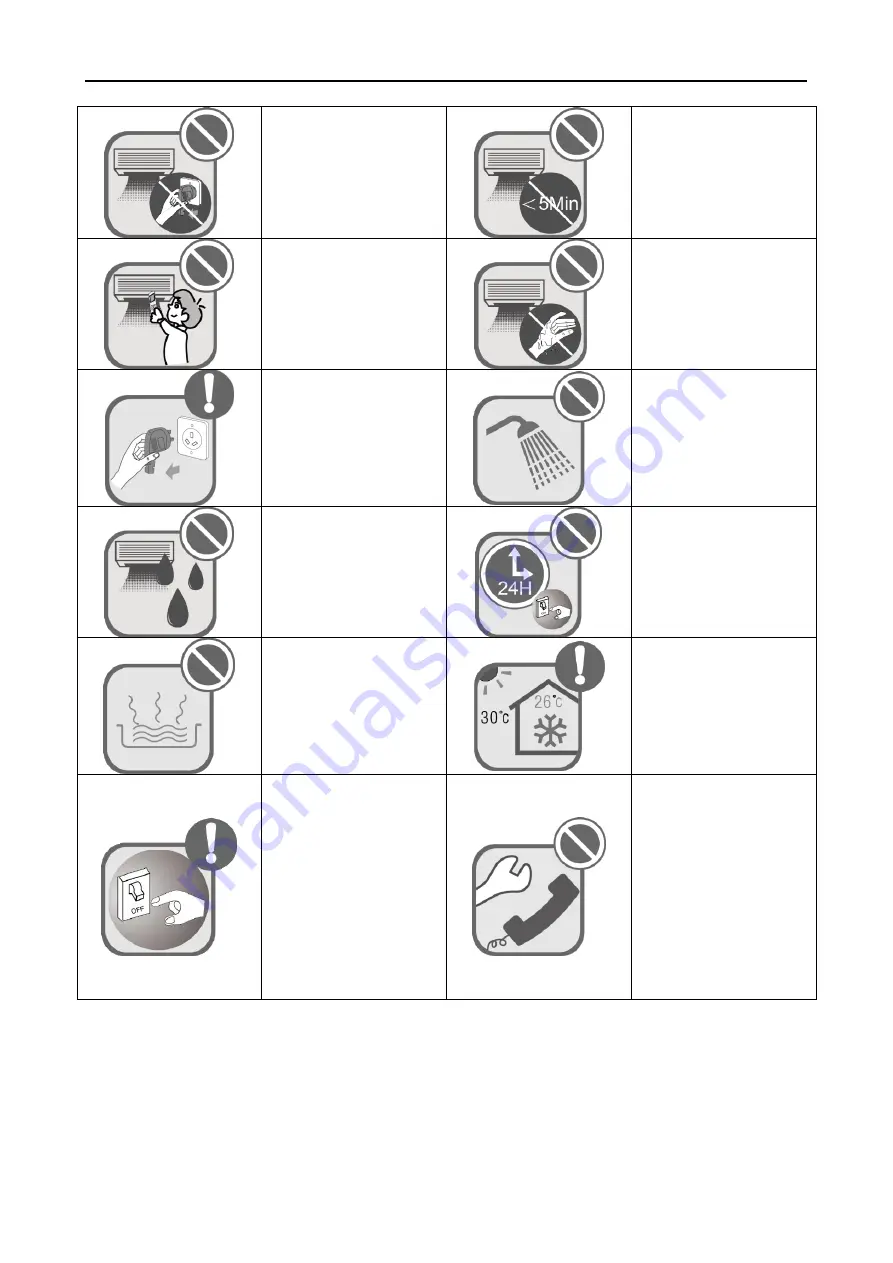

Do not operate or stop the

unit by inserting or pulling

out the power plug.

Do not turn off the unit until

it runs for at least 5 minutes.

Otherwise, oil return of the

compressor will be affected.

Children are not allowed to

operate the air conditioner.

Do not operate the air

conditioner with wet hands.

Please turn off and unplug

your air conditioner before

cleaning. Otherwise, electric

shock or personal injury

may occur.

Do not spray water on the

air conditioner or clean it

with

water,

otherwise

malfunction

or

electric

shock may occur.

Do not expose the air

conditioner directly under

damp

or

corrosive

surroundings.

Connect power 8 hours

before operation. Do not

disconnect power when you

want to stop the unit in a

short period of time, e.g. in

one night. (This is for

protecting the compressor.)

Volatile liquid like thinner or

gasoline will damage the

appearance of air

conditioner. (Please use

soft dry cloth and wet cloth

with mild detergent to clean

unit’s outer case.)

Under cool mode, do not set

the indoor temperature too

low. Keep the difference

between indoor temp and

outdoor temp within 5

℃

.

If abnormal condition occurs

(e.g. unpleasant smell),

please turn off the unit at

once and disconnect power

supply. Then contact Gree

authorized service center. If

the air conditioner continues

to operate despite of

abnormal condition, it may

be damaged and cause

electric shock or fire

hazard.)

Do not repair the air

conditioner by yourself.

Improper repair will cause

electric shock or fire hazard.

Please contact Gree

authorized service center

and ask professional

personnel to repair it.

Gree Electric Appliances, Inc. of Zhuhai will not assume responsibility for any personal injury or

property loss caused by improper installation, improper test running, and unnecessary repair or not

following the instructions of this manual.