33

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

3�3�6 Key Lock

At the homepage, by pressing the Up/Down keys simultaneously for 5 seconds, it is able to activate or

deactivate this function. When it is activated, any key operation is ineffective.

3�4 Precautions

Install the control following instruction shown in the figure below.

No�

1

2

3

4

Name

LCD

Communication line

Screws ST4.2X16

Rubber pad

Installation Steps

Step 1: draw the communication lines out from the LCD

Step 2: take four screws away from the rubber pad.

Step 3: remove the rubber pad off the LCD.

(3) After LCD is removed, unplug communication line according Fig 4.

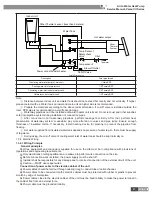

4 CONTROL WIRING DESIGN

Indoor Unit

Eletric box

Main board

Diplay board

CN4

AP

CN6

4

4

3

CN5

CN5

CN66 AP1

Main board

Outdoor Unit

Eletric box

Long-distance

Minitor PC

Installation Instruction :

(1) Wired controller connects to terminal CN6 on mainboard of indoor unit by 4-core communication line.

(2) The indoor unit connects to outdoor unit by 3-core communication line. Wiring terminal of indoor unit is

CN5 and that of the outdoor unit is CN66.

(3) Remote monitoring device connects to terminal CN4 of Display Board by 4-core communication line.

Summary of Contents for Versati II

Page 1: ...AIR TO WATER HEAT PUMP SERVICE MANUAL Versati T1 R410A 50Hz GC201308 II ...

Page 4: ...1 Air to Water Heat Pump Service Manual Versati II Series PRODUCT PRODUCT ...

Page 13: ...10 Air to Water Heat Pump Service Manual Versati II Series CONTROL CONTROL ...

Page 37: ...34 Air to Water Heat Pump Service Manual Versati II Series INSTALLATION INSTALLATION ...

Page 62: ...59 Air to Water Heat Pump Service Manual Versati II Series MAINTENANCE MAINTENANCE ...

Page 81: ...78 Air to Water Heat Pump Service Manual Versati II Series MAINTENANCE Fig 14 ...

Page 97: ...JF00301971 ...