CIP 1500 – User and Maintenance Manual

9

Chapter 3

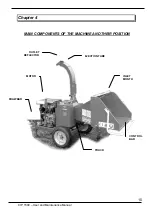

TECHNICAL DESCRIPTION OF THE MACHINE

The chipper Mod.

CIP 1500

has been designed and manufactured to reduce

large volumes of branches, sawmill waste and pruning remainders into small-

sized pieces.

The material, entered to the inlet port, is drawn by two feeding rollers against

the chipper disk.

The two draw rollers are driven by independent hydraulic motors with adjustable

speed.

The chipper disk, rotating at 1500 r.p.m., is fitted with 2 blades, cutting the

material into fragments, 5 to 20 mm long, and one counter-blade, secured to the

structure, further reducing them into chips.

The chips are ejected by the centrifugal action of the chipper disk into an outlet

conveyor.

Such conveyor may be oriented according to the outlet direction.

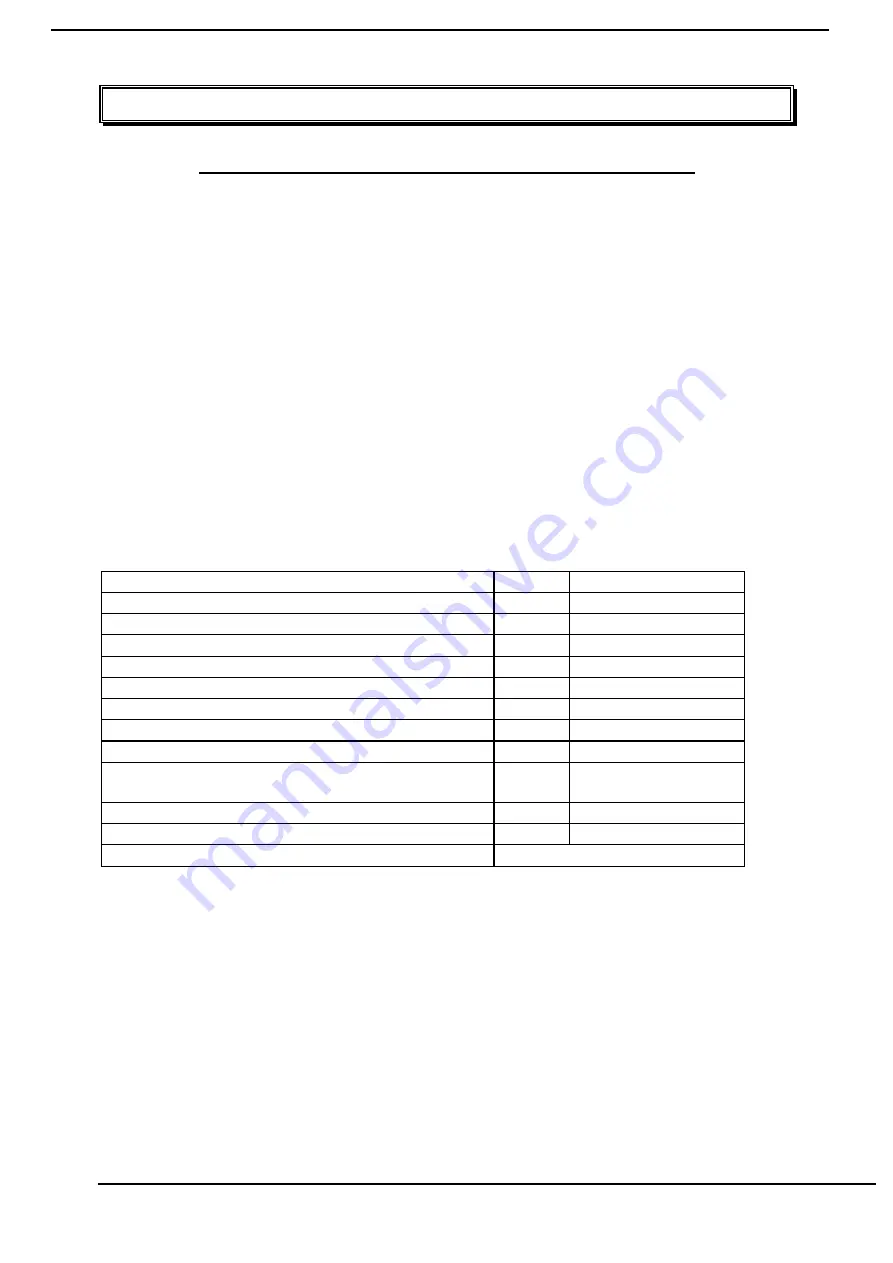

Technical Specification

•

Outlet month dimensions

mm

840 x 610

•

MAX chipping diameter

mm 150

•

Flywheel diameter

mm 680

•

Flywheel thickness

mm 30

•

Blades

n°

2 ÷ 3

•

Flywheel speed of rotation (max)

r.p.m. 1500

•

Chips length

mm

6 ÷ 12

•

Diameter of feeding rollers

mm 165-155

•

Max. distance between feeding rollers

mm 180

•

Stand-alone engine power rating

(LOMBARDINI / HONDA / ELECTRIC 22 kW)

kW

17.7 / 19.8 / 22 / 27.2

•

Hourly output

m

3

8 ÷ 10

•

Airborne noise produced by the machine

( 1 )

Db (A)

?

•

Weight

See data plate

( 1 ) The above-mentioned MAX noise level has been measured in the operator area, while he was

working.

?

Higher than 85 dB: wearing ear protectors is compulsory.