CIP 1500 – User and Maintenance Manual

29

Chapter

11

ROUTINE MAINTENANCE

CAUTION!

Risk of injury

Carrying out the above mentioned operations require wearing

safety gloves, goggles or face shield, ear protectors and safety

shoes.

CAUTION!

Before starting any servicing or setting operation, switch off the

engine and take off the key from the control panel.

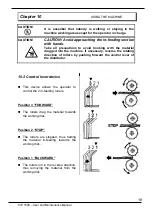

11.11 Lubricating the flywheel

supports

By means of a manual grease lubrication

pump, enter grease to the flywheel

supports

(V)

.

11.12 Lubricating the movable

roller slideways

Using a manual grease lubrication pump,

enter grease to the greasing nipple of the

slideway on the movable roller support

(G)

.

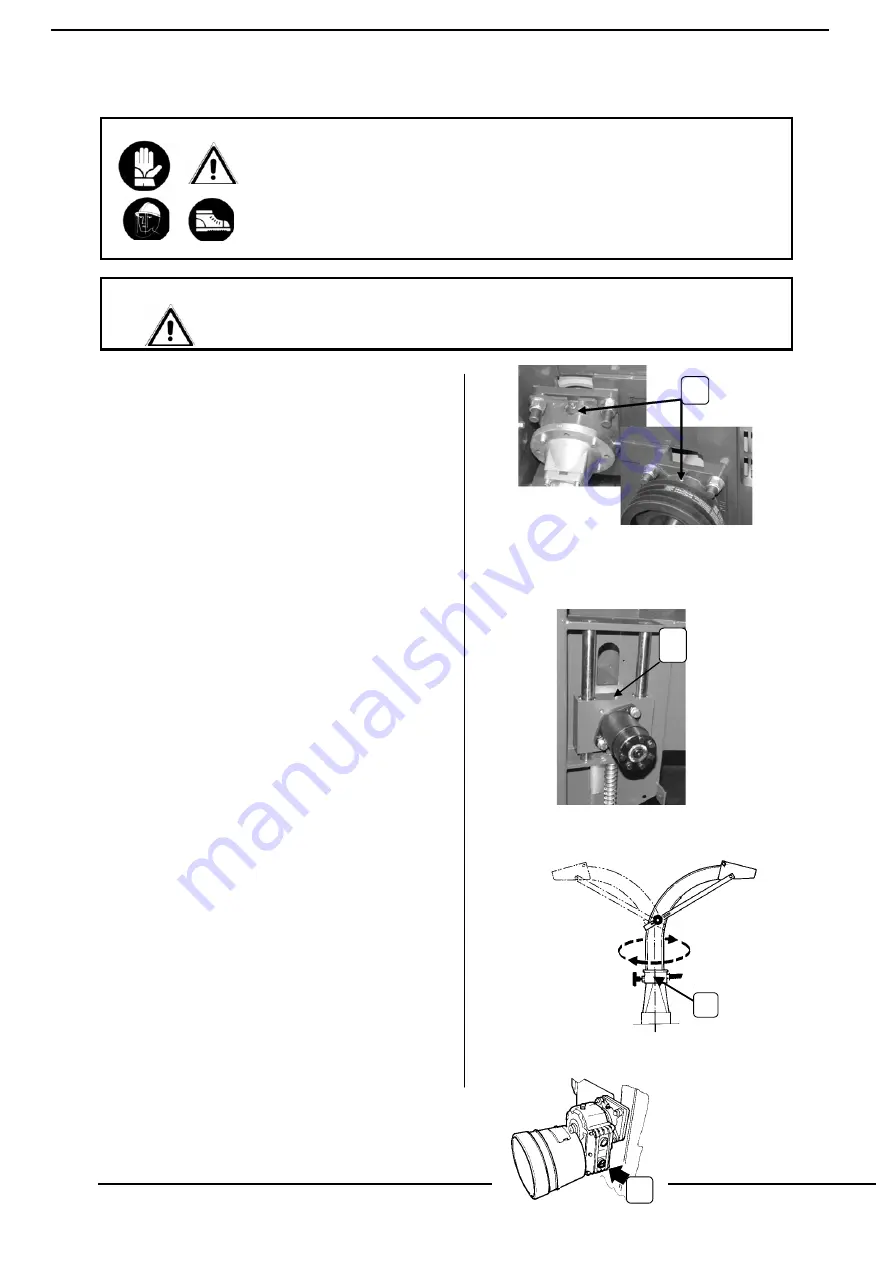

11.13 Lubricating the retaining

collar of the unloading

conveyor

From time to time, smear grease with a

brush on the retaining collar

(C)

of the

conveyor, in order to make its orientation

easier.

11.14 Checking oil level and

changing oil in the overdrive

(PTO version)

Check the oil level in the overdrive by

looking at the level gauge

(L)

and top up,

when required, using oil type

ROOL-OIL

EP 460

or equivalent.

NOTE: Oil has to be changed every

1000 working hours.

C

V

G

L