www.GreenSeriesFitness.com

©June 2015

Call Toll free at 800-269-7130

CIR-TM6000DC-G Revision 1.1

37

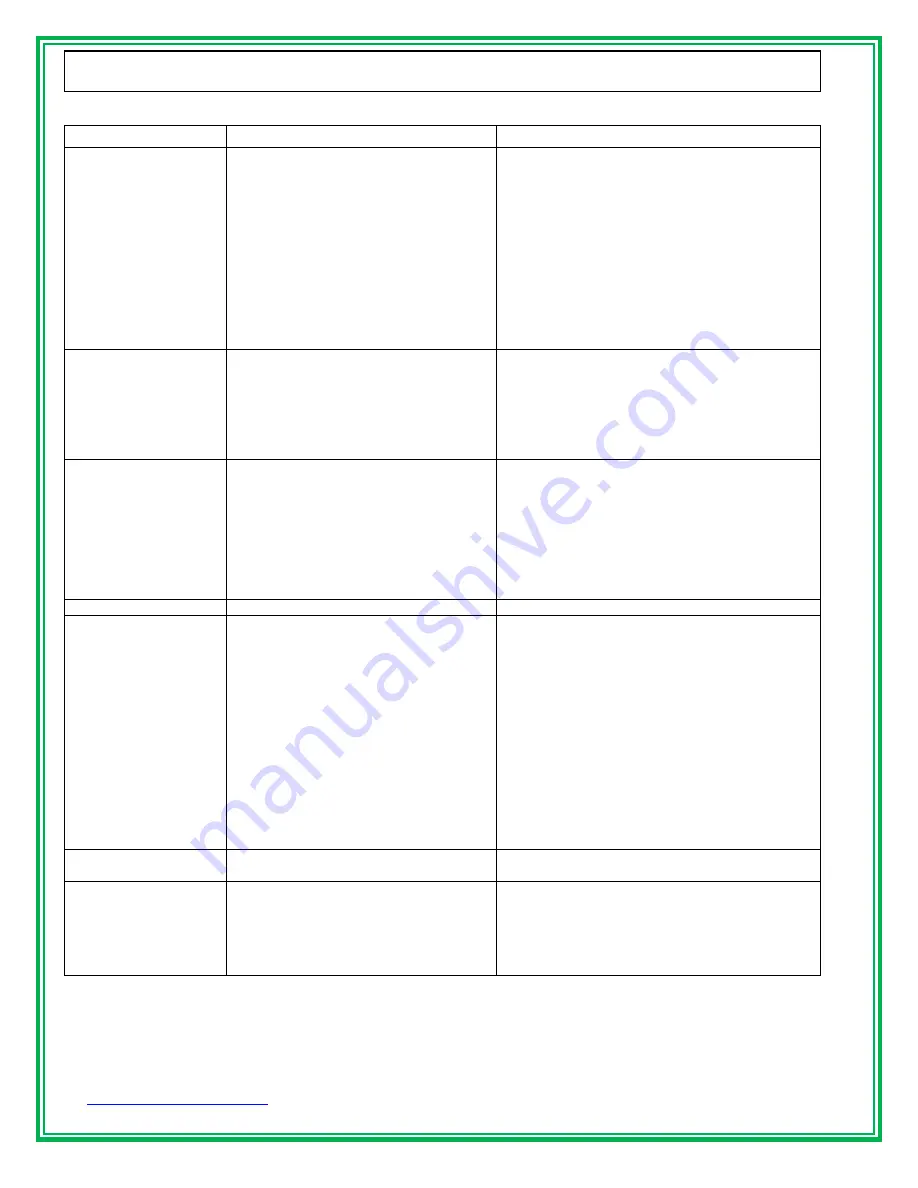

TROUBLE SHOOTING

SYMPTOM

CAUSE

SOLUTION

Console display does

not illuminate

A). No power to treadmill.

B). Console wire is not connected or

incompletely.

C). Overload, protecting is started.

D). Console power source damaged

A). Check the on-off switch is on, switch indicator

shall be on. If not, check AC power source.

B). Check console wiring connector points are

connected correctly, including outward and

connector point insert PINs.

C). Check fuse(near on-off switch) is working or not,

if working, push it back, and restart again, if not

working perform maintenance of the running belt

and deck.

D). Turn off power then open the motor cover, turn

on the power and check the console power pilot

lamp(LED2) on the interface PCB, it shall be light

completely, if not, replace it.

Display not completely

showing

A). Console damaged.

B). Console source power unstable.

A). Replace the console PCB.

B).

Turn off the ON/OFF switch, then open the

motor cover. Turn on the power again to see if the

interface power lights up or not. The interface

needs to be changed if the interface power doesn’t

light up or glitter.

Show SPEED ERROR

A). RPM sensor problem.

B). Driver system problem.

A). Turn off power and wait 15 seconds then turn on

again, press start, if motor works and then shows

SPEED ERROR, turn off power then open the

motor cover, verify the sensor wire is connect

correctly or replace it. If motor does not work, see

description of B).

B). Turn off power then open the motor cover,

replace the interface PCB, if does not work, replace

inverter.

Show E1

Memory device damaged.

Replace console PCB.

Show INCLINE ERR

Console cannot receive the incline motor

signal or signal error.

1. Reset power, if incline is working, check incline

wire and console wire connector for complete

connection, verify all connection points are

connected correctly, including outward and

connector point insert PINs.

2. If wires check ok but still show ERR, replace the

incline motor VR.

3. Reset power, if incline does not work, check the

incline operate pilot lamps LED4 (UP) & LED5

(DOWN) lights up or not when operating the incline

function, if does not light, check console wire or

replace interface PCB. If lights up, verify if the

motor is locked or not (maybe already at lowest

position and still move down, must be re-homing), if

not locked, replace interface PCB.

Show LUBRICATE

DECK

Prompt message advising you to lubricate

running belt.

After applying lubrication, press "Stop" to erase the

signal.

Showing Err

Communication between console and

inverter error.

A). Re-start the power, make sure if the console

wire damaged or connect pin bend.

B). Check the error message by engineering

manual instruction.

C). After re-start the power, if still present error,

replace the inverter.

If the supply cord is damaged, it must be replaced by the manufacturer or its service

provider or a similarly qualified person in order to avoid a hazard.