page 4/47

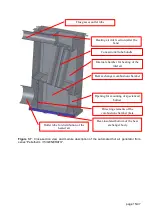

1. DESCRIPTION AND ADVANTAGES OF HOT AIR GENERATOR FROM SERIES

“PELLETHERM V.5/GENERATO”.

The series “Pelletherm V.5/GENERATO” are steel made biomass hot air generators used

for drying installations and heating of domestic, office, industrial premises and public facilities.

The hot air generators from series “Pelletherm V.5/GENERATO” utilize fuel, described below,

as the produced heat energy is transferred to the heat carrier – ambient air. The heated air

from the appliance is transferred to neighbor premises through air funnels from the heating

installation.

The appliance utilizes the following fuel types:

Dry nuts (from cherries, from morello);

Wood pellets with diameter 6, 8 to 14 mm, category ENplus-A1, ENplus-A2 and ENplus-B

according to standard EN 14961-2, or from category A, AB, B, BC, C, CD, E, EF according

to the manufacturing company methodic;

Mixture of pellets and nuts (for example in 50% - 50% ratio);

Pellets from other biomass (for example residues from the extraction of olive oil);

Pellets from other biomass, but after approved test in the hot air generator manufacturing

company laboratory;

The standard delivery kit of the generator “Pelletherm V.5/GENERATO” includes:

Hot air generator – 1pc;

Ash-tray – 1pc;

Legs for installation and leveling – 8pcs;

Pair of working gloves – 1pc;

Working apron – 1pc;

Installation and operation manual for the system – 1

р

c;

The appliance is equipped with:

Steel made heat-exchanger for heating of the heat-carrier – ambient air;

Fan supplying air for firing;

Fans for forced convection of the air heated by the generator;

Daily fuel hopper with volume 150 dm

3

which is able to store around 100 kg wood pellets.

The presented data is tentative because the real capacity of the fuel hopper depends on

the fuel bulk density, which in other hand depends on the particles size (wood pellets) and

their water content;

Control module, by which the operation parameters can be changed, in accordance to the

needs and specifics of every single installation and customer;

Ash residues container with capacity up to 5 kg;

The appliance is fitted with:

Automatic fuel firing system;

Ash residues automatic system for cleaning of the burner zone;

Transport auger system for automatic fuel feeding;

Advantages of the hot air generator:

The generator is designated to utilize different types of solid wood biomass, which feature

makes it flexible with regards to the used fuel and ecologically clean, it also does not

contributes to pollution and global warming of the planet;

Availability for heating neighbor premises by distributing the heated air out of the appliance

through outlet funnel;