FAN PERFORMANCE

System Dynamics

For a given flow rate (cfm), an air distribution system

produces a resistance to airflow (Ps). This resistance is

the sum of all static pressure losses as the air flows

through the system. Resistance producing elements

include ductwork, dampers, grills, coils, etc.

A fan is simply the device that creates the pressure

differential to move air through the system.

The greater the pressure differential created by the fan,

the greater the volume of air moved through the

system. Again, this is the same principle that relates to

water pumps. The main difference in our case is that

the fan is pumping air.

Tests have established a relationship between cfm and

Ps. This relationship is parabolic and takes the form of

the following equation:

Ps = K x (cfm)

2

Where K is the constant that reflects the “steepness” of

the parabola. This equation literally states that Ps

varies as the square of the cfm.

For example, whenever the cfm doubles, the Ps will

increase 4 times. The figures on the next page

graphically illustrate this concept.

The first two sections of this guide contain information

needed to select the right fan for the particular

application. The information in this section is useful

once the fan has been selected and installed on the job.

The fan curves and system resistance curves below will

help to solve fan performance problems that may be

encountered in a variety of applications.

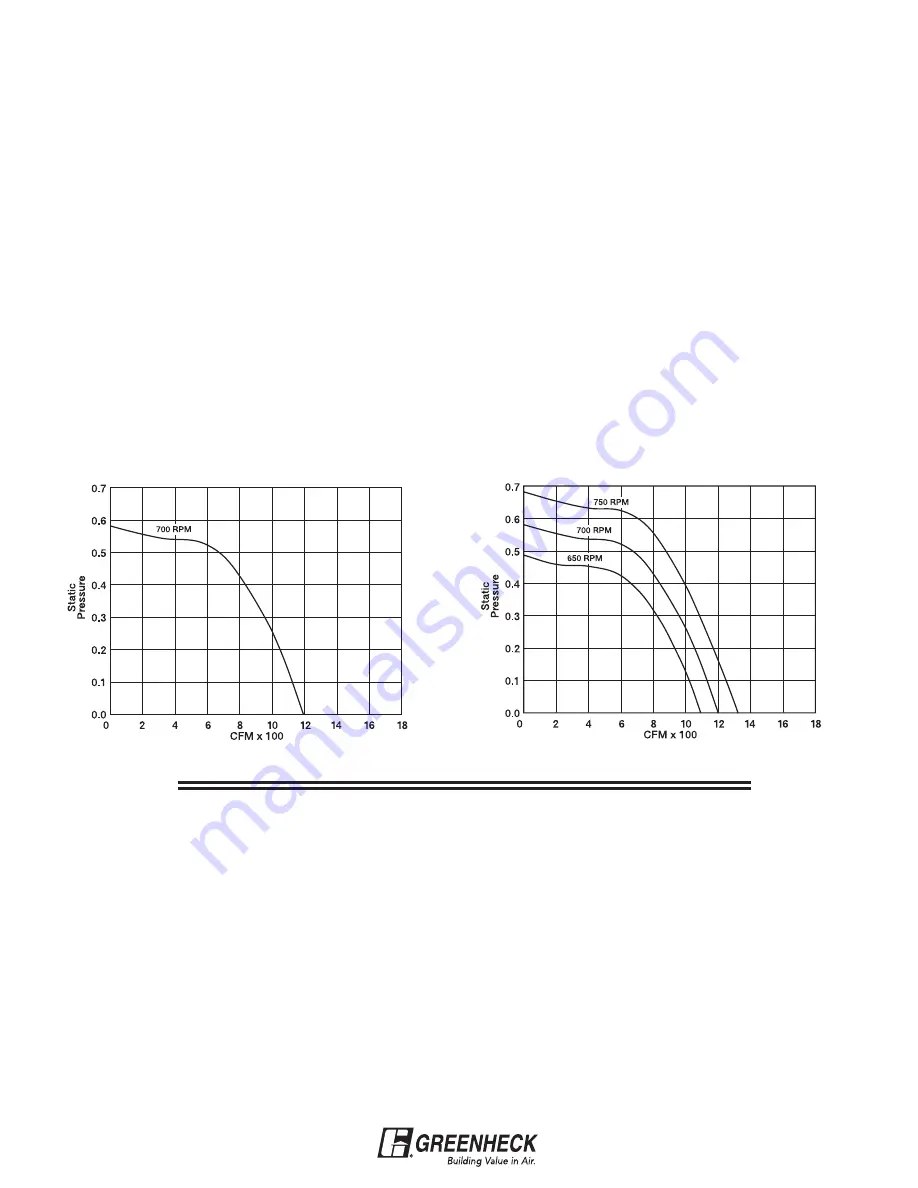

Fan Dynamics

A fan is simply an air pump. The rate at which a fan can

“pump” air depends on the pressure the fan must

overcome. This principle also relates to water pumps.

A water pump is able to deliver more water through a

2 in. diameter hose than a 1 in. diameter hose because

the 1 in. hose creates more resistance to flow.

For a fan, every flow rate (CFM-Cubic Feet per Minute)

corresponds to a specific resistance to flow (Ps-Static

Pressure). The series of cfm, Ps points for a fan at a

constant rpm is called a fan curve. A fan curve at 700

rpm is shown below.

At 0.25 in. Ps, this fan will deliver 1000 cfm. If the

pressure increases, cfm decreases. If the pressure

decreases, cfm will increase.

At 700 rpm, the operating point will slide along the fan

curve as static pressure changes, but it will never lie off

the curve. In order for a fan to perform at a point off the

curve, the rpm must be changed.

The figure below illustrates how rpm affects the fan

curve. Notice that the general shape of the curves are

the same. Changing rpm simply moves the curve

outward or inward.

21

Fan Curve

Varying Fan Curve