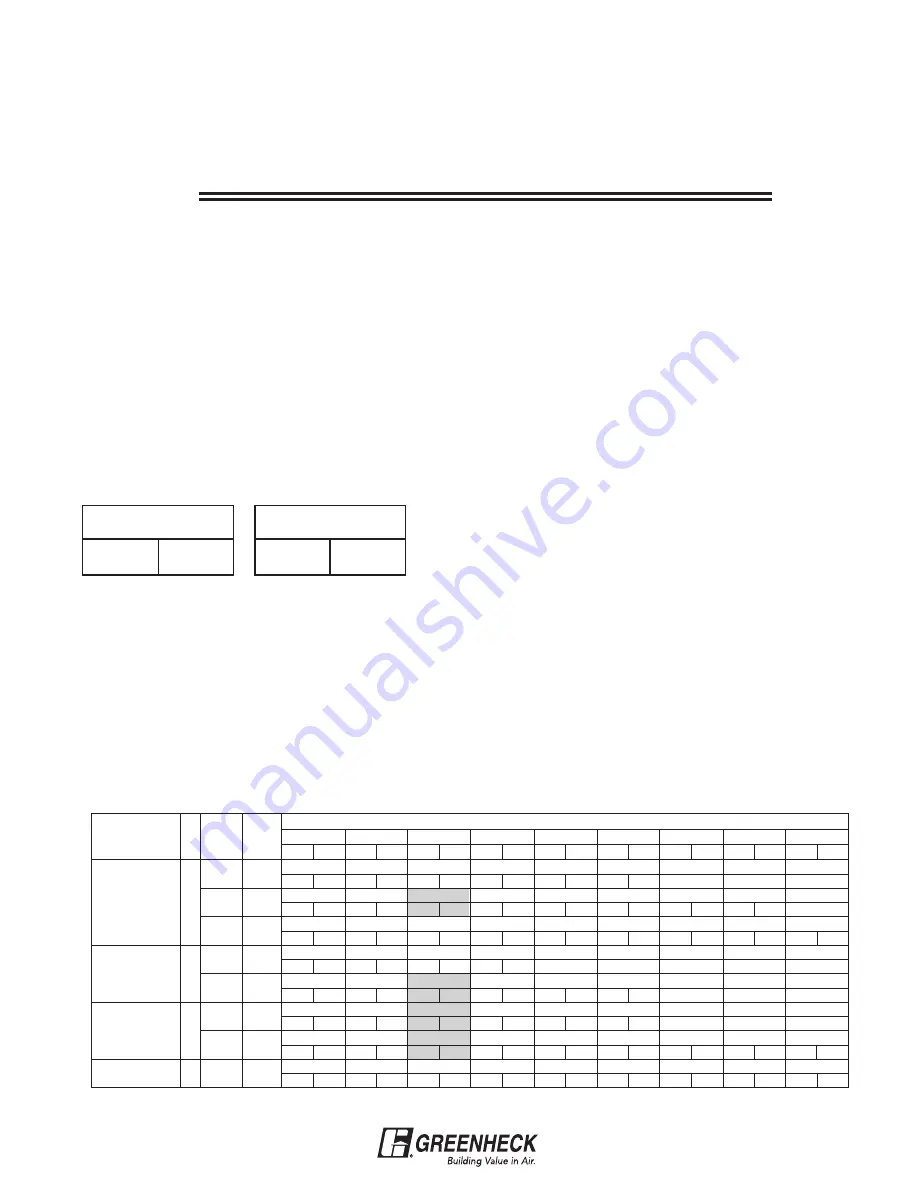

Reading Performance Charts

Assume that a job requires a belt drive roof exhauster

to move 1000 cfm against 0.25 in. Ps. Refer to the

performance model at the bottom of this page. Start at

the top of the chart with the 0.25 in. Ps column. (All

numbers in this column correspond to .25 in. Ps.) Now

follow the column downward until a value is found that

slightly exceeds 1000 cfm. In this case, 1012 cfm is the

first box that meets the requirements.

Note: Notice that each performance box is divided into

3 smaller boxes. The numbers refer to cfm, Sones and

Bhp.

Example:

At this performance point, the sone value is 11.1 and

the fan Bhp required is 0.16. Now by following the row

to the left, we can determine fan rpm and fan model.

In this case, the fan rpm is 1510 and the model is

GB-090-4 which has a 1/4 hp motor.

Notice that the GB-090-4 is not the only model to

choose from. If we follow the 0.250 in. Ps column down

further, we find a performance point at 1010 cfm.

At this point, the sone value is 7.9 and the Bhp is 0.14.

Following across to the left we find the rpm to be 1355.

The model is GB-101-4-R1, which also has a 1/4 hp

motor.

Both the GB-090-4 and the GB-101-4-R1 will perform

the air movement task equally as well. However, the

sound generated by the fan may have to be

considered. Compare the sone values: 7.9 sones for the

GB-101 and 11.1 for the GB-090. The GB-101 is about

30% quieter. Where a low sound fan is required, the

GB-101 would be a better selection. If loudness is not a

factor, the GB-090 would be a better selection because

it is less expensive.

Another possibility for this particular selection is a

GB-100-4-R2. Even though there is no performance

box showing close to 1000 cfm, there are two

performance boxes that bracket 1000 cfm. At 921 cfm

the fan will be running at 1260 rpm. At 1269 cfm the fan

will be running at 1635 rpm. Therefore, there is an rpm

for this model that will correspond to 1000 cfm

(obviously somewhere within the 1260-1635 rpm

range). As with all Greenheck belt drive fans,

intermediate cfm values are easily achieved by

adjusting the motor pulley (see illustration on next

page).

The most important part of selecting a fan is the ability

to read the performance charts. Most of the

performance charts in the catalog are similar and are

read in the same manner. Models RSF and BCF are

exceptions to this rule. The selection procedure for

these models is handled separately. Direct drive and

belt drive fans are also addressed separately.

Belt Drive Selection

CFM

Sone Bhp

1012

11.1 0.16

1030

957

884

807

725

632

10.1

0.11

9.9

0.12

9.6

0.12

9.3

0.12

8.8

0.13

8.5

0.13

1144

1078

1012

946

875

800

720

607

11.4

0.15

11.2

0.16

11.1

0.16

10.7

0.17

10.4

0.17

10.0

0.17

9.8

0.17

9.5

0.17

1295

1237

1179

1121

1061

999

934

866

785

13.4

0.22

13.3

0.23

13.2

0.23

13.0

0.24

12.7

0.24

12.4

0.25

12.1

0.25

11.8

0.25

11.6

0.25

906

818

731

607

6.0

0.060

5.4

0.065

5.0

0.070

4.3

0.070

1148

1077

1010

943

856

739

8.5

0.12

8.1

0.13

7.9

0.14

7.8

0.14

7.2

0.14

6.8

0.14

1067

991

921

840

735

385

7.6

0.099

7.1

0.104

6.8

0.112

6.5

0.115

5.9

0.115

4.4

0.083

1385

1325

1269

1214

1161

1094

1019

928

792

11.1

0.22

10.8

0.22

10.4

0.23

10.2

0.24

9.8

0.25

9.3

0.25

8.9

0.25

8.4

0.25

7.8

0.24

1525

1471

1418

1367

1320

1270

1208

1141

1064

13.2

0.29

12.8

0.30

12.5

0.30

12.3

0.31

12.2

0.33

11.3

0.33

10.8

0.33

10.6

0.33

10.1

0.33

STATIC PRESSURE / CAPACITY

0.000

0.125

0.250

0.375

0.500

0.625

0.750

0.875

1.000

Sone Bhp Sone Bhp Sone Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp

MODEL

(rpm RANGE)

RPM

TS

1360

3983

1510

4422

1710

5008

1070

3116

1355

3946

1260

3669

1635

4761

1800

5242

hp

GB-090-4

(1290-1710)

GB-101-4-R1

(1020-1400)

GB-101-3

GB-101-4-R2

(1260-1635)

1/4

1/4

1/4

1/3

5

Table 2